Introduction

An экскаватор consists of a boom, arm, bucket, and cab mounted on a rotating superstructure. It is required when moving big amounts of dirt. Because of these advancements, the digging power and maneuverability have been greatly enhanced. It has allowed them to perform a wide range of tasks. But there are different types of excavator that you must know.

Factors like performance, fuel economy, and versatility would determine the size and type of an excavator. This, in turn, will vary according to the type of work to be done. If you’re looking into renting or buying an excavator. You should know the differences between models and their advantages and disadvantages.

What Is An Excavator?

Simply, excavators are massive industrial machines used to move enormous quantities of material, such as soil and rock. Most commonly, excavators are used for digging, tunneling, earthwork, loading, and laying foundations. Excavators are the most effective and efficient piece of heavy equipment for these sorts of tasks.

These enormous machines work as high-pressure oil is delivered to the tracks’ hydraulic actuators via a hydraulic swivel. This allows for left-to-right motion and a full 360-degree rotation of the machine. The arm also accomplishes vertical and near-horizontal motions.

What are the 7 Most Common Types Of Excavators?

In this article, we’ll take a closer look at the several types of excavators available. Excavators come in a variety of forms, and some of the more common ones are described below.

Гусеничные экскаваторы

These machines, which resemble tanks but travel on two spinning tracks, are called crawlers. The machine is more stable on rough terrain due to the chain-wheel system. Crawler excavators are tracked machines that can dig, load, move soil, grade, lift, and carry materials.

The way they move might be used as a consideration for characterizing them. Crawler excavators are a type of multi-purpose excavator. A boom, arm, and bucket are positioned at the front of the machine. A crawler excavator can easily travel down and up hills because of its chain wheel system. Because of this, they are ideal for customizing the slope of steep or other irregular landscapes.

Crawler excavators may be slower than wheeled excavators, but they provide greater stability and versatility. Hydraulic power mechanisms in these excavators make them able to lift heavy waste and soil. Construction, mining, and quarrying are just a few sectors that benefit from crawler excavators.

Wheeled Excavators

Wheeled excavators are used for general excavation. Wheeled excavators are similar to crawlers in terms of size, design, and capability. The most noticeable difference is that these trains use wheels instead of tracks to move around. On smooth surfaces like concrete, asphalt, or a sports field, the use of wheels increases both speed and maneuvering.

Wheeled excavators are commonly used for roadwork and urban construction. They are more versatile in these locations, as wheels give less stability on uneven ground than tracks. They are not an ideal option in uneven conditions. Operators can attach outriggers to maintain stability when moving from a level surface to one with more undulations.

It is now possible to skillfully hop over obstacles like mailboxes, guardrails, and bridges. Wheeled excavators are preferable to tracked ones for roadside work. On the smooth ground, wheeled excavators can reach speeds of up to 22 mph. Having the ability to move around while working is helpful and can dramatically increase productivity.

Suction Excavators

A suction excavator is sometimes known as a vacuum excavator. It is a type of heavy machinery used to haul huge debris and materials out of the earth. A vacuum excavator is a popular tool for construction companies. It can be used in urban and suburban areas where there are dense residences. It has Limited noise and keeps pathways clean of trash.

This method of excavating around existing utilities makes the area safer for everyone involved. It is less mechanical and less obtrusive than traditional digging methods. To begin, the area to be excavated receives a blast of air or water to loosen the soil. A vacuum created allows the movement of soil and debris at those speeds.

The risk of damage is reduced by more than half when using a suction excavator. This makes them ideal for use in sensitive subsurface applications. If you want to do a sensitive activity with less risk of damage, precision is key. On the other hand, the large-scale use of narrow suction pipes is not feasible.

Long Reach Excavators

A long-reach excavator can reach further than a regular excavator since its arm is longer. When the topography or building site makes it impossible for the excavator and operator to get in close. This type of excavator can be the possible solution. The demolition industry makes heavy use of it, but that’s not all it can do.

A Longer Front Boom and Arm with a Unique Counterweight Design useful for both digging and leveling slopes. The layout facilitates easier use even in inconvenient places. The excavator has an extended arm that can reach farther than 100 feet horizontally. The arm is adaptable and can be fitted with several tools. Because of this, it can perform a wide range of additional operations.

These can include shearing, crushing, and cutting. The Super Long Reach Front can do light-duty excavation at vast distances. It is also designed for use in the building and maintenance of drainage canals. Long-reach excavators are built to be durable and are known for their low running costs and high output. Such excavators are, however, tricky to use in restricted spaces.

Hydraulic Shovels

It’s possible to use either wheels or tracks to move a hydraulic shovel, which is a heavy piece of equipment. Hydraulic shovels’ rams and propellers require pressure, which is supplied by the pumps operated by the engines. Mechanical shovels could be fueled by electricity or hydraulics.

A power shovel is a digging and loading machine that has a bucket. A hoist cable, with the digging bucket at its end, is suspended from it. It’s easy to spot this vehicle because of the dragline that connects the driver’s cabin to the bucket. By pulling the dragline, the bucket is lowered into the earth. Power shovels are another name for them. They can withstand the rigors of mining and other heavy-duty digging jobs.

Hydraulic shovels have many applications, but their primary use is in moving dust, debris, rocks, and heavy materials. They feature a substantial boom with a lifting arm/dipper shovel attached to it that can rotate at its base. The tool allows for faster work to be done. We can save up to 25% when we use a hydraulic mining shovel.

Dragline Excavators

A dragline excavator is a large piece of machinery utilized in civil engineering and surface mining. The size of the dragline excavator is unprecedented. Additionally, it has a unique mode of operation. The dragline excavator differs in both size and function from conventional excavators. A bucket is connected to the device through a hoist rope system and a hoist coupler.

The dragline that links the bucket to the cab is located on the opposite side of the bucket. The dragline pulls the bucket toward the operator while the hoist rope raises and lowers the bucket. Due to its hoist and dragline mechanism, this excavator is excellent for use in submerged environments. The most common uses for small draglines are highway and port development, foundation, and other civil works.

Larger draglines are essential for open-pit quarry mining. Both the maximum boom height and length impose severe constraints on the operational capabilities of draglines. Because of this, the dragline is limited in where it may dump the trash. The length of rope available for use severely limits the maximum digging depth of a dragline.

Skid Steers

The vast majority of skid-steer excavators have four wheels or tracks. The front and rear wheels on each side are mechanically connected so that they can turn in unison. Their main job is to dig up stuff and haul it around. These machines pack a tonne of oomph into small packages. This makes them ideal for tight spaces where plenty of work should be done.

Its small form factor makes it a good fit for tight quarters and congested work areas. These excavators can fit into tighter places and make tighter turns. Their attachments may stretch over the cab rather than around it. In instances when there is limited room and materials are scattered extensively.

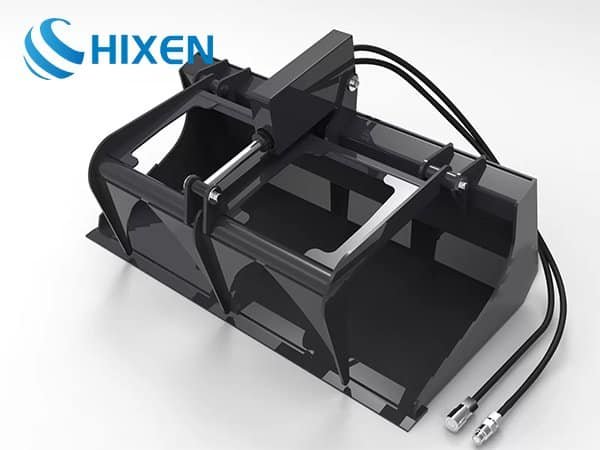

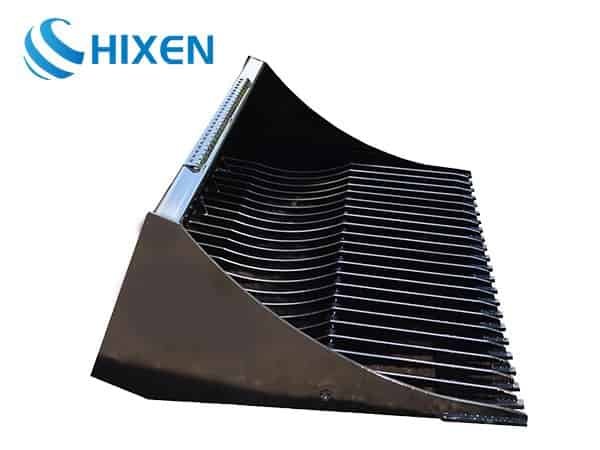

They are frequently employed when digging pools, cleaning sites, doing household tasks, and collecting waste. These excavators may be geared toward the needs of a particular job by simply switching out another attachment. Its compact size factor makes it a good fit for tight quarters and congested work areas. A skid steer lacking tracks can limit its usefulness on some surfaces, such as sand, snow, and mud.

Final Thoughts

Экскаваторы are very useful machines that can ease the work at construction and digging sites. The excavating and other lifting and hauling tasks are the most typical applications of these massive machines. There are notable differences between them in terms of power, gas mileage, and functionality. Each type is designed for a certain task; some are even specialized.

The relative merits of each variety determine the situations in which they excel. The operating environment and available resources will determine the type to be chosen.

HIXEN is one of the leading excavator manufacturers and suppliers based in China with 13 years of experience. The basic excavator models and even excavator parts are all available. We can help you if you want to purchase and re-sell any of these excavator machines. You can contact us at your convenience.