Finding the أفضل انزلاقية التوجيه المصغرة loader for your specific tasks can be a daunting task. The wrong choice could lead to inefficiencies, increased costs, and decreased productivity.

To choose a mini skid loader effectively, evaluate its engine power, weight capacity, terrain compatibility, and types of attachments it supports. Considering these elements ensures optimal performance and cost-effectiveness in every job.

To make an informed decision, assess the engine power, weight capacity, terrain adaptability, and attachment versatility of the mini skid loader. These factors are crucial for ensuring peak performance and cost-effectiveness in any job.

Continue reading to uncover the essential factors in choosing the right mini skid loader for your unique requirements.

Critical Factors in Mini Skid Loader Selection

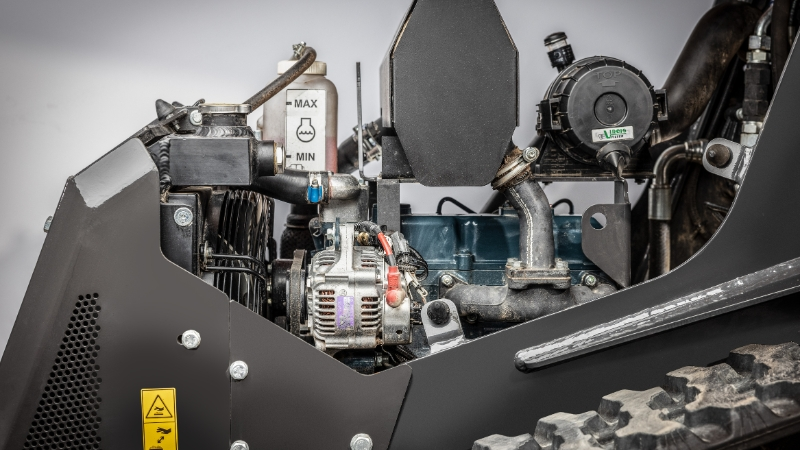

Several key factors influence the efficiency and appropriateness of a mini skid loader. These include weight capacity, engine power, hydraulic system, and terrain adaptability.

Select a loader by carefully considering weight capacity, engine power, terrain adaptability, and user-friendliness. Align these factors with the precise needs of your project to ensure a perfect match.

The weight capacity indicates how much material the loader can handle at once, which is vital for heavy-duty tasks in construction and landscaping. Engine power affects the speed and overall performance, particularly in demanding projects. The type of terrain also influences your choice: some loaders are designed for rugged terrains, while others are suited for smooth, level surfaces. Lastly, the strength of the hydraulic system determines the range of attachments it can support, enhancing the loader’s versatility across various applications.

Comparing Different Types of Mini Skid Loaders

Mini skid loaders are available in several types, each tailored to different work environments and project needs. Understanding the differences can simplify your decision-making process.

Mini loaders are categorized as track loaders and wheel loaders, each with its own set of advantages. Consider terrain compatibility and project requirements to select the most suitable type for your needs.

Track loaders provide superior stability and traction on uneven ground, making them ideal for outdoor construction and landscaping on rough or muddy terrains. Wheel loaders offer greater maneuverability and speed on smoother surfaces, such as pavements or warehouse floors. Mini crawler skid steer loaders and compact track loaders are better for heavy-duty applications, while articulated loaders excel in tight spaces with easy navigation. Each loader type caters to specific needs, so match its unique features to your project for maximum efficiency.

Attachments for Mini Skid Loaders

Attachments play a vital role in expanding the capabilities of a mini skid loader. From buckets to trenchers, each attachment serves a distinct purpose.

Mini skid loaders can be equipped with various attachments, enabling tasks ranging from digging to material handling. Consider the hydraulic capacity and attachment compatibility for the best results.

Attachments like buckets, pallet forks, augers, and trenchers allow loaders to perform a wide range of tasks, from lifting materials to digging trenches. For landscaping projects, attachments such as mulchers and soil conditioners are invaluable, while augers and stump grinders aid in tree removal and ground preparation. It’s crucial to select a loader with a hydraulic system capable of supporting your preferred attachments to maximize versatility and functionality. Attachments vary in cost and power requirements, so understanding their type and compatibility can save time and boost productivity on-site.

Top & Best Mini Skid Steer Loader Brands

Selecting a brand known for durability and customer support is essential. The best brands offer unique benefits tailored to diverse project needs.

Reputable brands deliver reliable mini skid loaders with a focus on performance, durability, and attachment compatibility. Consulting brand reviews can help identify trustworthy manufacturers.

Highly regarded brands are often recognized for their robust hydraulic systems, advanced attachment options, and exceptional durability. Customer reviews and ratings can reveal a brand’s reputation, especially concerning ease of use, maintenance, and customer support. Some brands focus on affordability, while others provide premium features. When choosing a brand, consider how well it aligns with your project needs and budget. Dependable brands often include warranties and spare parts, ensuring lower long-term maintenance costs and a solid return on investment.

Price Factors of Mini Skid Loaders

The prices of mini skid loaders vary based on factors such as engine power, weight capacity, attachments, and brand reputation. Understanding these factors can assist you in budgeting effectively.

Loader prices are influenced by specifications like engine size, weight capacity, and brand reputation. Opt for essential features within your budget for the best cost-efficiency.

Loaders with higher weight capacity and engine power typically cost more due to their advanced capabilities in handling challenging tasks. Compatibility with additional attachments can increase the price, as loaders with high hydraulic power support more options. Brand reputation also impacts pricing, with premium brands often charging more for reliability and advanced features. However, more affordable options may still offer high performance for light to medium tasks. Knowing these factors helps you balance performance with budget considerations effectively.

Benefits of Using a Mini Skid Loader in Landscaping

In landscaping, mini skid loaders offer flexibility, power, and precision, enabling contractors to complete detailed tasks efficiently.

Mini skid loaders excel in landscaping, featuring a compact design, maneuverability, and a range of versatile attachments. They boost productivity for tasks such as trenching, planting, and clearing.

Mini skid loaders stand out in landscaping due to their ability to navigate tight spaces and perform detailed tasks like trench digging, soil leveling, and material transport. Attachments like augers and grapples make them highly versatile for various aspects of landscaping projects, from planting trees to setting posts. Their compact size minimizes ground disturbance, while advanced hydraulic systems ensure smooth operation. By reducing the need for multiple types of equipment, mini skid loaders lower labor and operational costs, making them an efficient choice for landscapers focused on precision and detail.

Maintaining a Mini Skid Loader

Regular maintenance is crucial for keeping a mini skid loader in top condition, extending its lifespan, and ensuring consistent performance.

Key maintenance steps include inspecting hydraulic systems, cleaning the loader, and checking fluids. Routine care enhances durability and performance, reducing repair costs.

Loader maintenance involves inspecting hydraulic lines, cleaning the undercarriage, checking engine fluids, and ensuring attachments are secure and functioning correctly. The hydraulic system is particularly vital, as leaks or pressure drops can compromise loader performance. Tire or track conditions should also be regularly monitored to avoid operational risks on various terrains. Scheduled maintenance is essential for protecting your investment, with specific care steps like filter changes, lubrication, and storage in clean, dry environments prolonging loader life. Adhering to a maintenance schedule ensures the loader is always ready for demanding tasks.

Choosing a Best Mini Skid Steer Loader Within Your Budget

Selecting a mini skid loader within your budget requires balancing performance needs with cost considerations, focusing on key specifications rather than premium features.

To stay within budget, prioritize essential features such as weight capacity and engine power over luxury options. Consider gently used loaders for additional savings.

Budget-conscious buyers can find cost-effective loaders by concentrating on core capabilities rather than high-end features. For instance, if your project mainly involves lifting lighter materials, a mid-range engine and hydraulic system can save costs. Another option is to consider purchasing used or refurbished loaders from reliable sellers, allowing access to quality machines at lower prices. Finally, choose loaders with fewer but crucial attachments to keep costs down without sacrificing versatility. Balancing core needs and budget ensures you get a loader that performs well without overspending.

Maximizing Efficiency with a Mini Skid Loader

Maximizing the efficiency of your mini skid loader involves proper training, selecting the right attachments, and planning tasks to reduce downtime.

Efficiency improves when operators know how to utilize attachments effectively and follow strategic task planning. Proper use reduces fuel consumption and saves time.

Training operators on attachment use and optimal loader handling reduces fuel costs and speeds up task completion. Plan projects to minimize loader travel distances and maximize each attachment’s utility, for example, by using augers only when all digging tasks are aligned. Also, choosing a loader with easy maintenance access can save downtime between tasks. Efficient use extends beyond loader capabilities; knowing when to switch attachments or adjust speed based on terrain saves time and reduces wear, ensuring your loader performs optimally for longer.

Conclusion:

Choosing the best mini skid steer loader entails evaluating factors like weight capacity, engine power, and attachment compatibility, ensuring you select the best machine for your tasks and budget.