مقدمة

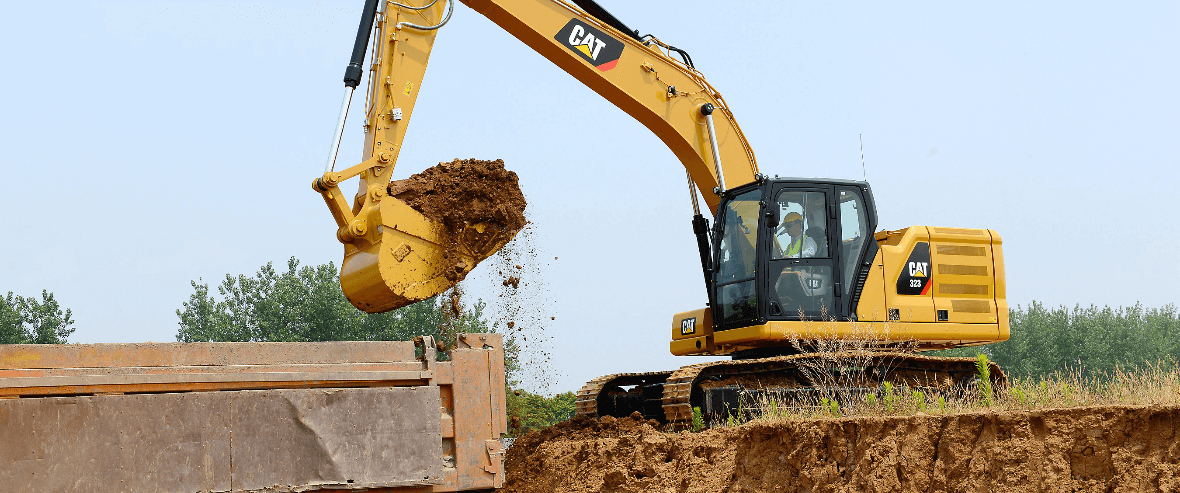

When it comes to construction or excavation projects, choosing the right equipment is crucial for success. A tracked excavator is a versatile and robust machine that can handle various tasks, from digging trenches to demolishing buildings.

However, not all excavators are created equal, and selecting the right one for your needs can be daunting. That’s why it’s essential to consider the top 10 features to look for in a track excavator. These features include:

- الحجم والوزن

- Power and Performance

- Digging Depth and Reach

- Bucket Capacity and Attachments

- Mobility and Maneuverability

- Operator Comfort and Safety

- Maintenance and Serviceability

- Fuel Efficiency and Emissions

- Control System and Automation

- Cost and Value

We will discuss these features in detail. After reading this blog post, you can choose a tracked excavator to meet your needs and expectations.

- الحجم والوزن

When choosing a track excavator, size and weight are crucial factors. The size of the tracked excavator determines how much material it can move, while the weight affects its stability and performance. Consider the size and weight of the tracked excavator in relation to your job site and the materials you need to move.

If you’re working in tight spaces or need to transport the tracked excavator frequently, a smaller, lighter model may be more appropriate. On the other hand, more extensive and heavier-tracked excavators are better suited for bigger jobs.

Finding the right balance between size and weight will ensure your tracked excavator performs efficiently and effectively. Next, We’ll discuss the power and performance features of tracked excavators.

- Power and Performance

Power and performance are key factors to consider when choosing a tracked excavator. The excavator’s engine horsepower and hydraulic system determine its digging and lifting capabilities. You’ll want to choose an excavator with sufficient power to handle the materials you need to move and the depth of your excavation. A more powerful engine and hydraulic system will allow you to tackle complex jobs, increasing productivity and efficiency.

Speed and precision are also essential performance features. Look for an excavator with responsive controls and smooth operation for greater accuracy and productivity.

Choosing an excavator with the right power and performance features can quickly and efficiently complete any job. Let’s discuss digging in depth and reaching features of the tracked excavator

- Digging Depth and Reach

The digging depth and reach are crucial when choosing a tracked excavator. The digging depth refers to how deep it can dig, while the reach refers to the distance from the excavator’s pivot point to the end of its arm.

You’ll want to choose a tracked excavator with the right combination of digging depth and reach to handle your job requirements. Consider the depth of the excavation you need to make and the materials you need to move. A deeper digging depth may be necessary for foundation work, while a longer reach may be required for demolition or forestry work.

Choosing a tracked excavator with the appropriate digging depth and reach will easily handle any job. Bucket capacity and attachments are essential to consider, too; let’s discuss them.

- Bucket Capacity and Attachments

The bucket capacity and attachments are essential when choosing a tracked excavator. The bucket capacity determines how much material the excavator can move at once, while the attachments expand the excavator’s versatility. Consider the size and type of materials you need to move and the attachments required for your specific job site requirements.

For instance, a larger bucket capacity may be necessary for moving heavy materials. At the same time, specialized attachments such as augers or breakers may be needed for drilling or breaking through hard surfaces.

Choosing a tracked excavator with the correct bucket capacity and attachments will allow you to complete your job quickly, efficiently, and with minimal manual labor. Mobility and maneuverability are essential when working on complex sites; let’s discuss them.

- Mobility and Maneuverability

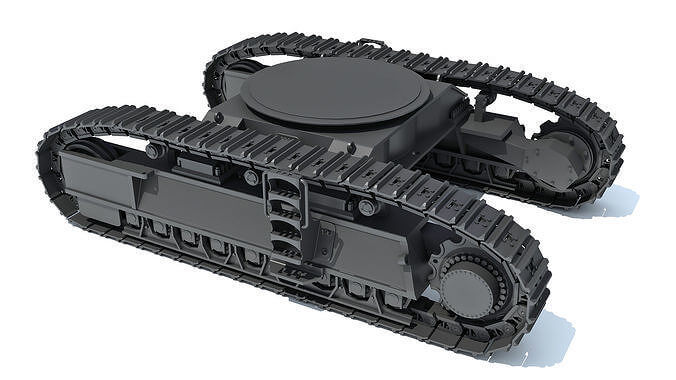

The mobility and maneuverability of a tracked excavator are essential factors to consider when choosing one for your job site. The size and weight of the excavator will determine how easily it can move around the job site and whether it can fit into tight spaces or navigate uneven terrain.

Look for an excavator with a powerful and efficient engine and durable tracks to ensure smooth movement and stability. In addition, consider the tracked excavator’s turning radius and swing angle to ensure it can maneuver in tight spaces and around obstacles.

Choosing a tracked excavator with mobility and maneuverability will allow you to complete your job quickly and efficiently while minimizing damage to the surrounding environment.

- Operator Comfort and Safety

The operator’s comfort and safety are crucial when choosing a tracked excavator. Look for an excavator with an ergonomic and comfortable cabin that is designed to reduce fatigue and strain on the operator. The cabin should also be equipped with air conditioning and heating systems to ensure a comfortable working environment, regardless of the weather conditions.

The tracked excavator should have safety features such as a backup camera, alarms, and automatic shut-off systems for the operator’s and the environment’s safety. Proper training and certification for the operator are also essential to ensure the safe and efficient use of the excavator.

Choosing an excavator with operator comfort and safety features will improve productivity and reduce the risk of accidents and injuries. Next, we will discuss maintenance and serviceability features when choosing the right-tracked excavator.

- Maintenance and Serviceability

Maintenance and serviceability are essential features to consider when choosing a tracked excavator. To reduce downtime and maintenance costs, look for an excavator with easy access to all maintenance points, such as oil filters and air cleaners.

tracked excavator with a diagnostic system that can detect and alert you to potential issues before they become more serious problems. Ensure that the excavator is equipped with high-quality components, such as hydraulic pumps and hoses, to reduce the likelihood of breakdowns and the need for costly repairs.

Choosing an excavator with reliable customer support and service from the manufacturer or dealer is also essential. Selecting an excavator with good maintenance and serviceability features will save you time and money in the long run and ensure its peak performance.

- Fuel Efficiency and Emissions

Fuel efficiency and emissions are essential when choosing a tracked excavator. Look for an excavator with an efficient engine that can provide maximum power while minimizing fuel consumption.

tracked excavators with emissions-reducing features such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), reduced emissions and comply with local regulations. It’s also important to consider the type of fuel the excavator requires and whether it is readily available in your area.

Choosing a fuel-efficient and low-emission excavator can save money on fuel costs, reduce your carbon footprint, and contribute to a cleaner environment. The operating system of the tracked excavator is essential to consider; that’s why we will discuss the control system and automation of tracked excavator.

- Control System and Automation

Control systems and automation features are important considerations when choosing a tracked excavator. Look for a tracked excavator with intuitive and easy-to-use controls that allow you to operate the machine efficiently and effectively.

Consider tracked excavators with automation features such as auto-leveling, auto-digging, and GPS guidance systems that can help increase productivity, reduce operator fatigue, and improve accuracy. Choose a tracked excavator compatible with various attachments and easily switch between tasks.

Consider the level of technology included, such as touchscreens and telematics systems that can provide real-time information on the machine’s performance and location. Selecting a tracked excavator with advanced control and automation features can improve productivity, reduce downtime, and maximize your investment.

- Cost and Value

Cost and value are crucial factors to consider when choosing a tracked excavator. Look for an excavator that offers a balance between cost and value. While the initial purchase price is essential, you should consider the long-term value, including its durability, reliability, and resale value.

Additionally, consider the cost of ownership, including maintenance, repairs, and fuel consumption, to ensure that the excavator is a cost-effective investment.

Choose an excavator from a reputable manufacturer or dealer, and check customer reviews and ratings to ensure you get a high-quality product. By selecting a cost-effective and valuable excavator, you can maximize your return on investment and ensure that your construction projects run smoothly and efficiently.

خاتمة

In conclusion, choosing the right-tracked excavator for your construction needs requires careful consideration of various factors. From size and weight to power and performance, digging depth and reach, bucket capacity and attachments, mobility and maneuverability, operator comfort and safety, maintenance and serviceability, fuel efficiency and emissions, cost, and value, and control system and automation features.

Every factor ensures that your construction projects run smoothly and efficiently. By carefully evaluating your needs and considering these top 10 features, you can select a tracked excavator that perfectly fits your project and budget, ensuring success and satisfaction.