Excavadora Ripper: herramienta innovadora definitiva

El desgarrador de excavadora es un accesorio vital para las excavadoras, diseñado para romper suelos difíciles, rocas y materiales compactados. Ofrece beneficios como mayor eficiencia, versatilidad, ahorro de costos y mayor seguridad. Con varios tipos, parámetros y características, se usa ampliamente en construcción, minería, paisajismo y construcción de carreteras, lo que facilita mucho las tareas de movimiento de tierras.

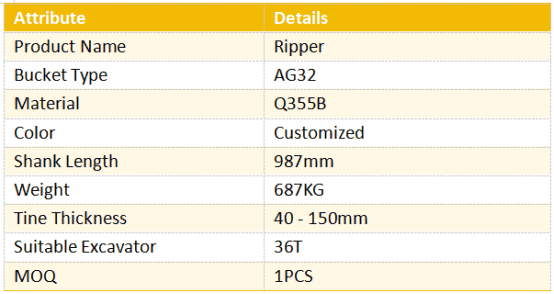

Información adicional

¿Qué es un destripador de excavadora?

Un destripador de excavadora es un accesorio de alta resistencia diseñado para usarse con excavadoras para romper tierra dura y compactada, roca, asfalto u otros materiales resistentes. Funciona de manera similar a un arado o un rastrillo, utilizando una hoja o dientes afilados y puntiagudos para penetrar la superficie y aflojar el suelo. Normalmente utilizado en minería, construcción y limpieza de terrenos, el desgarrador de excavadora mejora significativamente la productividad en tareas que requieren romper terrenos y excavar en condiciones difíciles.

Parámetros del destripador de excavadora

Tipos de desgarrador de excavadora

- Destripador de un solo diente

Un desgarrador de un solo diente tiene un solo diente grande y resistente diseñado para romper tierra compactada o roca blanda. Es ideal para trabajos de intensidad media en aplicaciones de construcción y minería. - Destripador de dientes múltiples

Los desgarradores de dientes múltiples tienen múltiples dientes afilados que permiten una mayor cobertura de superficie y una penetración más rápida en el suelo. Estos se utilizan comúnmente en proyectos de mayor escala donde se necesita una preparación del terreno más rápida y efectiva. - Destripador de rocas

Esta versión del desgarrador presenta características de diseño y durabilidad mejoradas para atravesar superficies extremadamente duras, incluida la roca sólida. Por lo general, se utiliza en minería, canteras y grandes proyectos de construcción. - Destripador de escarcha

Diseñados específicamente para atravesar terrenos congelados o compactados, los desgarradores de heladas están reforzados para soportar la alta resistencia que plantea la tierra helada o compactada. - Destripador de servicio pesado

Las cremalleras de alta resistencia están diseñadas para usarse con excavadoras grandes y son capaces de afrontar las tareas más difíciles, como romper capas gruesas de roca y suelo compactado en movimientos de tierra profundos.

Vídeo de trabajo del destripador

Características del destripador de excavadora

- Durabilidad: Fabricados con acero o aleación de alta resistencia, la mayoría de los desgarradores están diseñados para durar años de uso intensivo.

- Alta resistencia al desgaste: Las puntas del desgarrador suelen estar recubiertas con carburo de tungsteno u otros materiales para garantizar un rendimiento duradero en condiciones difíciles.

- Dientes ajustables: Algunos desgarradores vienen con dientes ajustables que se pueden reposicionar según la naturaleza del suelo o la roca que se está excavando.

- Sistema de montaje rápido: Los desgarradores generalmente están diseñados para conectarse y retirarse fácilmente de la excavadora, ya sea a través de sistemas de pasadores o mecanismos de acoplamiento rápido.

- Diseño ergonómico: Los desgarradores están diseñados teniendo en cuenta la eficiencia y a menudo incorporan características ergonómicas para un mejor control y operación durante el uso.

Aplicaciones comunes del desgarrador de excavadora

- Excavación de rocas: Los desgarradores de excavadoras se utilizan comúnmente en operaciones de minería y canteras para atravesar capas de roca dura, lo que facilita la extracción de materiales valiosos.

- Rompimiento de suelos y limpieza de terrenos: En proyectos de desarrollo de tierras, el desgarrador se utiliza a menudo para romper el suelo compactado o quitar grandes tocones y raíces de árboles.

- Construcción de carreteras: Los desgarradores son cruciales para despejar caminos para carreteras y autopistas, particularmente en terrenos rocosos o irregulares. Pueden romper el terreno difícil de forma rápida y eficiente.

- Trabajos de zanjas y cimientos: Los desgarradores de excavadoras se utilizan ampliamente en la excavación de cimientos y zanjas para servicios públicos, ya que pueden atravesar fácilmente suelo compactado y suelo duro.

- Excavación en terreno helado o helado: En climas más fríos, los desgarradores de heladas ayudan a atravesar la tierra helada, lo que permite que los proyectos de construcción avancen incluso en los meses de invierno.

- Preparación de tierras agrícolas: Los desgarradores se pueden utilizar en agricultura para preparar la tierra para plantar rompiendo capas de suelo compactadas o superficies duras.

Color personalizado

P1: ¿Cuál es la diferencia entre un desgarrador y un cucharón en una excavadora?

La principal diferencia es que un desgarrador está diseñado para romper y aflojar superficies duras como rocas y tierra compactada, mientras que un cucharón se usa para recoger y mover tierra, arena y grava. Los desgarradores suelen tener dientes o cuchillas afiladas para la penetración, mientras que los cucharones tienen superficies planas o curvas para sujetar y mover materiales.

P2: ¿Puedo utilizar un desgarrador de excavadora para excavar tierra o roca?

Sí, los desgarradores de excavadoras están diseñados específicamente para atravesar materiales resistentes como rocas, suelo compactado y suelo congelado. Son perfectos para proyectos que requieren romper o aflojar superficies duras.

P3: ¿A qué profundidad puede excavar un desgarrador de excavadora?

La profundidad que puede alcanzar un desgarrador de excavadora depende del tamaño del desgarrador y de la excavadora que se utiliza. En promedio, los desgarradores pueden penetrar a profundidades de hasta 3 metros (aproximadamente 10 pies).

P4: ¿Es fácil de mantener el desgarrador de la excavadora?

Sí, los desgarradores de excavadoras son relativamente fáciles de mantener. El mantenimiento regular implica revisar y reemplazar las puntas o dientes de desgaste, lubricar el accesorio e inspeccionar los componentes de montaje en busca de desgaste.

P5: ¿Cómo elijo el desgarrador adecuado para mi excavadora?

El desgarrador adecuado depende del tamaño de la excavadora, el tipo de suelo o roca con el que trabajará y las necesidades específicas de su proyecto. Es importante seleccionar un destripador con la capacidad y las características adecuadas para realizar sus tareas de forma eficaz.

Contáctenos

Productos destacados

A lo largo de los años, HIXEN se ha centrado en la innovación tecnológica y la fabricación de precisión. Comenzó con miniexcavadoras, ahora la excavadora mediana, la cargadora y la minicargadora están bastante maduras. Eche un vistazo a los productos destacados y obtenga una cotización instantánea de inmediato si tiene interés.

Productos relacionados

-

Una herramienta poderosa para la limpieza de tierras y el manejo de materiales eficientes.

Leer más -

Pulgar hidráulico: mejore el poder de agarre de su excavadora

Leer más -

Abrazadera de pulgar hidráulica: accesorio para excavadora eficiente y versátil

Leer más -

Cucharón estrecho para excavadoras: excavación de precisión para espacios reducidos

Leer más