Skid steers are indispensable equipment for construction, agriculture, and other heavy industries. However, just like any machine, they can experience malfunctions that disrupt operations. Understanding the common problems and solutions for skid steer repair is crucial to keeping your machine running smoothly and minimizing downtime.

Skid steer repair typically involves addressing issues related to the engine, hydraulic system, transmission, and other components. Regular maintenance and timely repairs are essential to prolong the lifespan of your skid steer. Learn about the most common problems and how to solve them to keep your equipment in top condition.

In this article, we’ll dive into the most common skid steer issues, how to diagnose them, and practical repair solutions that can help prevent costly downtime.

What are the most common issues with skid steers?

Skid steers are robust machines, but like all mechanical equipment, they can experience failures. Whether it’s the engine, hydraulics, or the transmission, knowing the most common issues will help you maintain your machine and avoid expensive repairs.

Common skid steer problems include engine failures, hydraulic leaks, transmission issues, and electrical malfunctions. These issues often arise due to poor maintenance, improper usage, or wear and tear over time.

- Engine Problems: One of the most frequent issues with skid steers is engine failure. Symptoms like starting problems, overheating, or unusual noises can indicate engine trouble. To prevent these issues, regular oil changes, air filter replacements, and timely inspection of fuel injectors and spark plugs are necessary.

- Hydraulic Problems: Hydraulic fluid leaks are another common issue. A leaking hose, damaged pump, or low fluid levels can lead to decreased performance or a total failure of the hydraulic system. Always check hydraulic fluid levels and look for leaks around hoses, fittings, and the pump.

- Transmission and Drive System Issues: Transmission problems, such as slipping or a lack of power, can occur in skid steers. These issues are often linked to worn-out belts, hydraulic pressure issues, or damaged drive components. Inspecting and maintaining these parts regularly can avoid major transmission repairs.

How to diagnose skid steer repair issues?

Diagnosing skid steer repair issues accurately is essential for efficient and cost-effective repairs. Knowing how to spot the symptoms of various problems early can prevent costly breakdowns and keep your equipment operating at its best.

To diagnose issues, listen for unusual sounds, check for leaks, and observe performance changes. Using a diagnostic tool like an OBD scanner can help pinpoint electrical or engine faults.

- Visual Inspection: A thorough visual inspection can reveal issues such as leaks, worn components, or signs of overheating. Check the hydraulic hoses, engine oil levels, and the undercarriage regularly.

- Diagnostic Tools: Using an OBD scanner or a similar diagnostic tool can help identify engine or transmission issues. These tools connect to the skid steer’s onboard system and provide error codes, which can be useful in pinpointing the exact cause of the malfunction.

- Systematic Checks: Start by checking fluid levels, the battery condition, and looking for any visible damage. For hydraulic issues, inspecting the pumps and hoses is crucial. Electrical problems are often evident through malfunctioning lights or unresponsive controls, which can be checked using a multimeter.

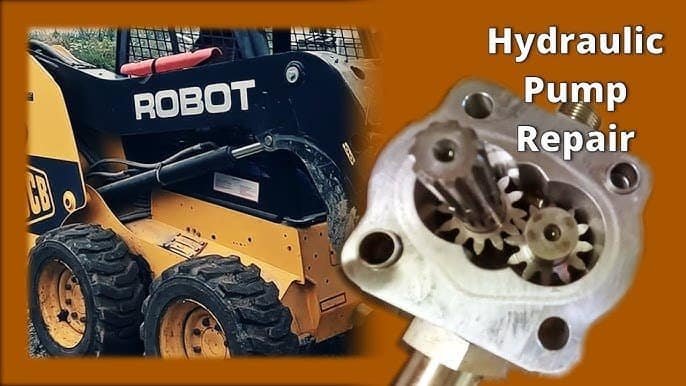

How to repair hydraulic problems in skid steers?

Hydraulic systems are at the core of a skid steer’s functionality, powering the lifting arms, buckets, and other attachments. When these systems fail, the machine can become virtually useless. Knowing how to address hydraulic issues will save time and money.

Common hydraulic problems include oil leaks, pump failures, and clogged filters. Repairing these issues may involve replacing hoses, seals, or the pump itself. Regular checks of the hydraulic fluid and filtration system can prevent major issues.

- Hydraulic Fluid Leaks: Leaking hydraulic fluid can lead to loss of pressure and reduced lifting capacity. Inspect hoses and seals regularly. If you find a leak, replacing the affected part is crucial before further damage occurs.

- Pump Issues: If the pump is malfunctioning, it can result in slow or unresponsive hydraulics. This often requires replacing the hydraulic pump or repairing its components. Regular fluid changes and keeping the system clean can extend the pump’s lifespan.

- Filter Clogs: A clogged filter can cause the hydraulic system to work inefficiently. Always change the filter on schedule and clean the hydraulic reservoir to prevent contaminants from affecting performance.

What are the solutions to engine and transmission problems in skid steers?

Engine and transmission issues in skid steers are serious problems that require prompt attention. Addressing these issues early can save you from costly repairs and long downtimes.

Engine and transmission problems often involve failure to start, overheating, or slipping. Solutions include cleaning fuel injectors, replacing belts, and checking the transmission fluid levels.

- Engine Maintenance: If your skid steer’s engine won’t start, check the fuel and battery first. If there’s no fuel flow or the battery is weak, these are easy fixes. More complex issues may involve replacing fuel injectors or addressing cooling system problems, such as a blocked radiator.

- Transmission Repairs: For transmission issues, check the fluid levels and look for leaks. Low transmission fluid or dirty fluid can cause poor shifting or slipping. Regular fluid changes and checking the drive belt tension can prevent these issues.

- Prevention: Regular engine maintenance, including oil changes, air filter replacements, and coolant checks, will extend the life of your engine. Also, keep the transmission system clean and replace filters and fluids as necessary.

How much does it cost to repair a skid steer?

The cost of repairing a skid steer can vary significantly depending on the nature of the problem and the parts that need to be replaced. Knowing what to expect can help you plan your maintenance budget more effectively.

Repair costs for skid steers can range from a few hundred to several thousand dollars, depending on the severity of the issue. Engine or transmission repairs tend to be more expensive, while minor issues like replacing filters or hoses are cheaper.

- Labor Costs: Labor costs can vary depending on your location and the complexity of the repair. On average, you can expect to pay anywhere from $75 to $150 per hour for labor.

- Parts Costs: The cost of parts can vary greatly. Simple components like filters and hoses are relatively inexpensive, while major engine or transmission parts can cost thousands of dollars. You can save on parts by purchasing from reputable suppliers or considering used components for non-critical parts.

- Preventative Maintenance: Regular maintenance can help avoid more expensive repairs. Scheduled fluid changes, belt inspections, and hydraulic checks are crucial in preventing issues that would lead to costly repairs.

What is the average life of a skid steer?

The average life of a skid steer depends on its usage, maintenance, and brand. On average, a well-maintained skid steer lasts between 5 to 10 years.

A skid steer can last around 5,000 to 10,000 hours of operation, depending on its usage and care. Regular maintenance and proper usage can help extend its lifespan significantly.

- Factors Affecting Lifespan: The lifespan of a skid steer can be affected by how often it is used, the type of work it performs, and the maintenance schedule. Machines used in harsh conditions or overloaded frequently will have a shorter lifespan.

- Extending Lifespan: To get the most out of your skid steer, follow the manufacturer’s maintenance schedule, regularly check fluid levels, and address minor issues before they become major problems.

Are skid steers high maintenance?

Skid steers are designed for heavy-duty work, but they do require regular maintenance to ensure optimal performance. Understanding their maintenance needs can help you avoid excessive repair costs.

Skid steers are not overly high-maintenance machines, but they do require routine checks and maintenance. Regular oil changes, hydraulic fluid checks, and cleaning are necessary to keep the machine in good condition.

- Routine Maintenance: Performing basic maintenance tasks like changing filters, checking hydraulic fluid, and cleaning air filters will reduce the need for major repairs. Also, keeping the undercarriage clean and inspecting the tires or tracks will help prevent unnecessary wear and tear.

- Preventative Maintenance: Implementing a preventative maintenance program will ensure your skid steer remains in top shape, lowering the risk of breakdowns and costly repairs.

Bobcat skid steer repair and Case skid steer repair

Bobcat and Case are two of the most well-known skid steer brands, but each has its unique repair challenges. Understanding the specific issues these brands face will help you make informed decisions about repairs.

Bobcat and Case skid steers may face issues related to their respective engines, hydraulic systems, or electrical components. Regular maintenance and brand-specific repair knowledge can help keep these machines running smoothly.

- Bobcat Skid Steer Repair: Bobcat models are known for their durability, but common problems include hydraulic leaks, engine issues, and transmission failures. Make sure to use OEM parts for repairs to maintain performance.

- Case Skid Steer Repair: Case skid steers are built for rugged work, but like Bobcat, they can face hydraulic system issues, fuel injector problems, and electrical malfunctions. Using the right diagnostic tools and repair manuals can save you time and effort.

Hixen skid steer repair

Hixen skid steers are designed for reliability, but occasional repairs may be necessary. Understanding the common repair needs of Hixen models will help you maintain your equipment efficiently.

Hixen skid steer repair often focuses on hydraulic and engine components, as well as regular wear and tear on moving parts. Proper care and using genuine parts can prolong the lifespan of your Hixen skid steer.

Regular Maintenance for Hixen: To avoid unexpected repairs, adhere to Hixen’s recommended maintenance schedule, which includes checking hydraulic systems, oil changes, and inspecting electrical systems.

HIXEN will give away wearing parts such as filter elements, seals, etc. when shipping skid steer loaders, as well as a full set of maintenance tools.

Resumen

Understanding common skid steer repair issues and solutions can help you maintain your equipment efficiently. Regular maintenance, early detection, and brand-specific care can minimize downtime and extend the life of your skid steer.