Choosing the right types of excavator buckets for your project can significantly affect efficiency and costs. Understanding different bucket types and their functions will help you make a more informed decision for better performance.

To choose the right excavator bucket, consider factors like soil type, job size, load requirements, and budget. Different buckets serve different purposes, so knowing what each type is best suited for will help you find the most efficient option.

In the following sections, we will explore various types of excavator buckets and provide guidance on how to select the best one for your specific project needs.

What Are the Different Types of Excavator Buckets?

Excavator buckets come in a wide variety of designs, each tailored to specific tasks. Knowing the differences between these types will ensure that you choose the most suitable one for your project.

Common types of excavator buckets include standard, heavy-duty, trenching, and clamshell buckets. Each bucket type is optimized for specific work conditions and tasks.

- Standard Bucket: Ideal for general excavation tasks, these are the most common type of bucket. They are designed for efficiency in moving soft to medium soils, making them versatile for most jobs.

- Heavy-Duty Bucket: Built for tougher conditions, such as rocky or dense soil, heavy-duty buckets have reinforced sides and are often used in more demanding environments.

- Trenching Bucket: Designed with a narrow profile, trenching buckets are ideal for digging narrow, deep trenches for utilities or drainage work.

- Clamshell Bucket: These are specialized for grabbing and handling loose materials like sand, gravel, or demolition debris. They have a clamshell-like design and are perfect for handling bulk materials.

How Many Types of Excavator Buckets Are There?

There are numerous types of excavator buckets, each designed for a specific task. Choosing the right one depends on understanding the needs of your project and the terrain you’ll be working with.

In addition to the common types like standard and heavy-duty buckets, there are more specialized options such as snow buckets, trash buckets, and even frost buckets for extreme conditions.

Excavator buckets come in many variations, including:

- Snow Bucket: Designed for snow removal, these buckets have a shape that minimizes snow buildup and allows for effective removal in winter conditions.

- Trash Bucket: Used for cleaning up construction debris, this bucket is ideal for handling large quantities of loose, light materials.

- Frost Bucket: Specifically built to handle frozen or compacted soil, frost buckets have extra-strength materials to dig through hard, frozen earth.

What Is the Bucket of an Excavator Called?

The primary tool for digging and material handling in an excavator is commonly referred to as the “bucket.” It’s an essential component of the machine, responsible for carrying out various excavation tasks.

The bucket is the attachment on an excavator used to dig, scoop, and move materials. The bucket’s design and capacity vary based on the type of work it is meant for.

The “bucket” can also be called the “digger bucket” or “excavator bucket,” depending on regional terminology. In some cases, specific types of buckets are named after their function, such as the grading bucket for land leveling or the trenching bucket for digging trenches.

What Are the Different Types of Bucket Wheel Excavators?

Bucket wheel excavators are large-scale machines used in mining and heavy excavation work. These machines feature a continuous digging mechanism that uses a rotating wheel with buckets attached.

Bucket wheel excavators come in various types, such as traditional, double-wheel, and mobile versions, designed to meet different excavation needs.

- Traditional Bucket Wheel Excavators: These are stationary machines designed to work in mining operations where large-scale earthmoving is required. They use a large wheel with attached buckets that scoop and transport material continuously.

- Double-Wheel Excavators: These machines feature two bucket wheels, allowing for faster excavation and greater material handling capacity, often used in high-demand mining operations.

- Mobile Bucket Wheel Excavators: These machines are built to be mobile, moving along tracks or rails to follow the excavation process. They are perfect for sites with changing excavation needs.

What Are the 5 Buckets?

Understanding the five most common types of excavator buckets is crucial for selecting the one that best fits your job requirements. These buckets are designed for different soil conditions and tasks.

The five main types of excavator buckets are the standard, heavy-duty, grading, trenching, and clamshell buckets. Each is specialized for specific tasks, making it essential to understand their differences.

- Standard Bucket: Perfect for everyday excavation tasks in soft to medium soils.

- Heavy-Duty Bucket: Reinforced for harder soil conditions, such as rocky or compacted earth.

- Grading Bucket: Ideal for grading and leveling tasks due to its flat design.

- Trenching Bucket: Narrower and deeper for digging precise trenches.

- Clamshell Bucket: Specialized for lifting loose materials and bulk goods.

Are All Excavator Buckets the Same?

Excavator buckets are not all the same. Different tasks, soil types, and work conditions require specialized buckets designed to perform efficiently.

The variety in excavator bucket designs is vast. From standard buckets to highly specialized options like frost buckets or ripper buckets, each is engineered for a specific purpose.

Each bucket type is engineered for specific soil conditions, project types, and material handling tasks. Whether you need a robust bucket for tough rock excavation or a finer design for grading, choosing the right type will enhance productivity and reduce wear and tear.

What Is a Ripper Bucket?

A ripper bucket is a specialized bucket designed to break through tough or frozen ground. It’s often used in mining or construction sites where the soil or terrain is too hard for traditional buckets.

Ripper buckets feature a sharp, pointed design that helps to break apart compacted or rocky soil. They’re ideal for preparing the ground before traditional excavation work begins.

Ripper buckets are essential for projects involving heavy-duty terrain, such as rocky surfaces, frozen earth, or compacted materials. They often feature reinforced tips for durability, allowing excavators to effectively prepare sites for further digging.

Can You Dig with a Grading Bucket?

Grading buckets are designed for leveling and grading work, but they can also be used for digging tasks where precision and surface finish are critical.

While grading buckets are not typically used for heavy digging, they can be used for more shallow digging tasks, particularly where ground leveling and smooth finishes are necessary.

Grading buckets are often employed for landscaping, road construction, and site preparation. Their flat design makes them ideal for removing surface material while maintaining a consistent level.

What Is the Difference Between a Grading Bucket and a Ditching Bucket?

Grading buckets and ditching buckets serve different purposes. Understanding the distinctions between these two can help you choose the right one for your project.

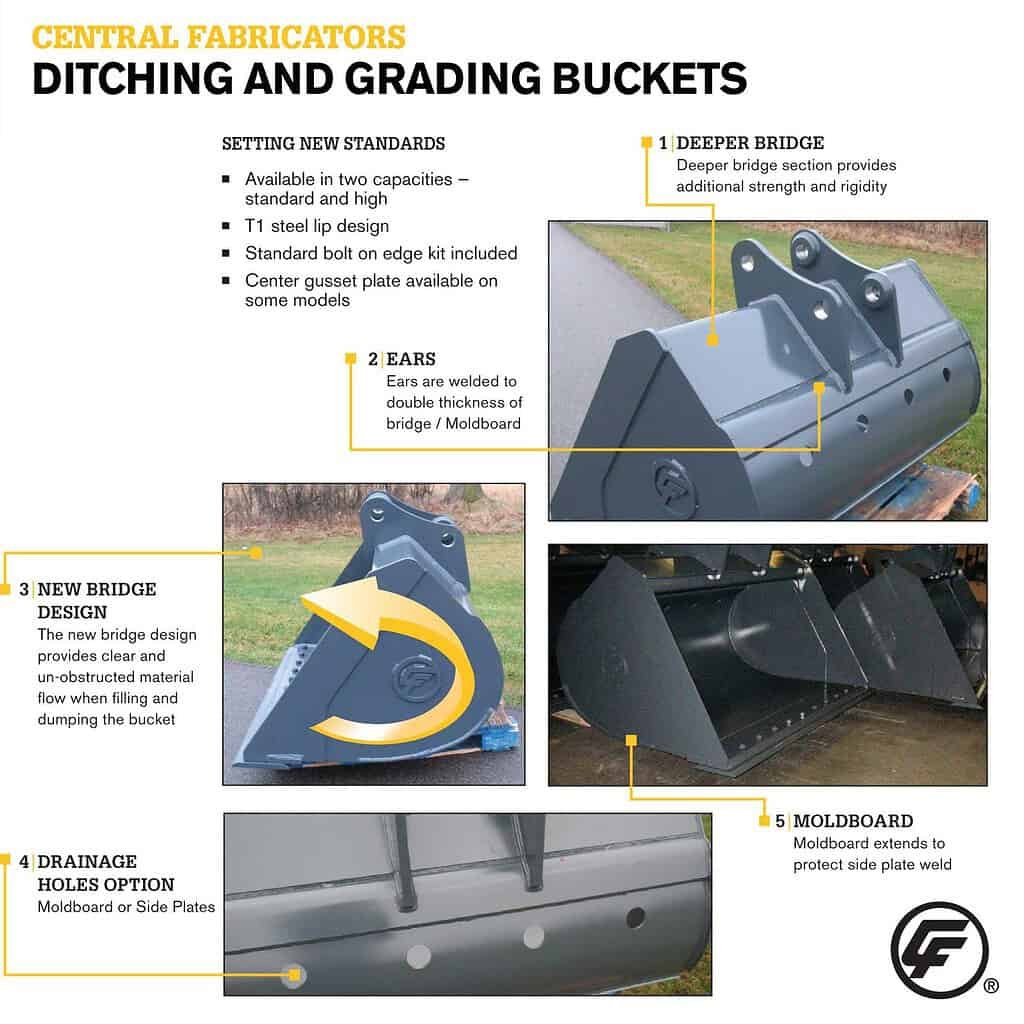

Grading buckets are designed for leveling and smoothing the ground, while ditching buckets are intended for digging trenches and ditches, often with deeper, more precise digging capabilities.

- Grading Bucket: Typically has a flat, wide blade to level and smooth surfaces, ideal for tasks like site preparation and landscaping.

- Ditching Bucket: Features a deeper, narrower profile designed for digging trenches or channels, making it essential for utility installations or drainage work.

Résumé

Choosing the right excavator bucket involves considering soil type, project requirements, and bucket functionality. With the right bucket, you can optimize your work efficiency, reduce wear and tear, and lower overall project costs.