Introduction

Skid steer loaders are one of the most common construction machines used in various applications. Because of the versatility of attachments, they deliver superior performance and are quite popular in modern construction works.

Skid steers are available with either wheels or tracks. Both are compact loader machines with short turning radius. This article has everything that you should know about a skid steer loader. Let’s continue reading and exploring the skid steer loader.

Qu’est-ce qu’une chargeuse compacte ?

UN chargeuse compacte is also known as skid steer, SSL, or skid loader. It is a rigid-frame, small, engine-powered machine equipped with lift arms. You lift the arms of skid steer loaders with multiple attachments to complete different jobs. A skid steer loader may consist of two tracks or four wheels to run on the ground.

If you got a wheel loader, you should know that the right-side wheels of the loader are independent of the left-side wheels. This is possible due to two independent and separate transmissions; one for left-side wheels and the other for right ones. Forward and reverse clutch drives were used in the earlier versions of skid steer loaders.

It is important to note that modern skid steer loaders built and designed since the 1970s use two independent hydrostatic transmissions. Skid steer loaders, like micro diggers or excavators, are used for multiple purposes. It is a lightweight and maneuverable machine with different attachments.

Keeping in mind the structure of your skid steer loader, you may think about how to turn it. It is possible when the operator increases the speed of the wheels on one side. It drags or skids the wheels across the ground when rotating in the opposite direction. This process is known as the steering function. Experts named the skid steer due to this function.

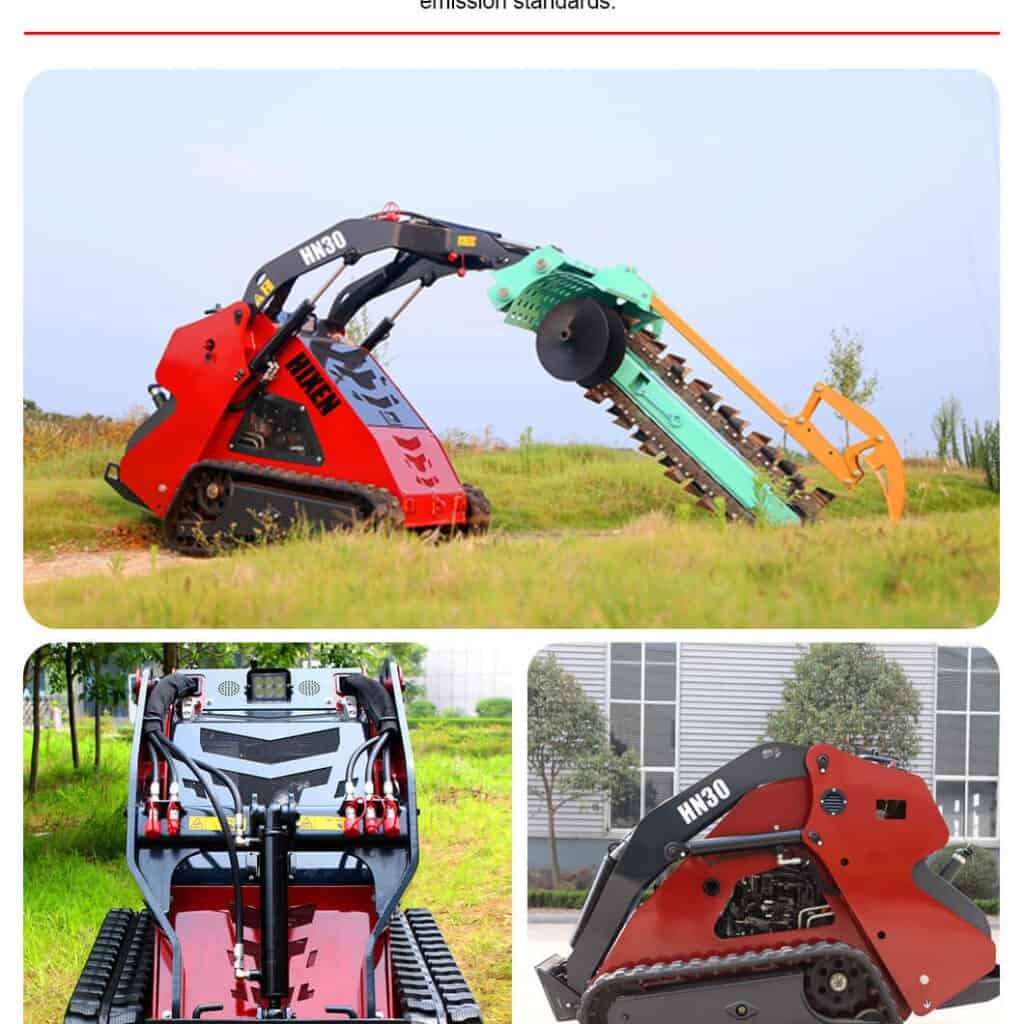

Compact or Mini Skid Steer Loader

Besides the normally known skid steers, there is also a smaller one without a cabin. That is called a chargeur compact de bouffée de dérapage or mini skid steer loader. For this kind of machine, we just need to stand on the back side of it, and all the control panels and buttons are on hand. They are especially useful when the working area is confined and tight. Though compact in body, it also enjoys a high versatility.

What Kind Of Attachments For Skid Steers

- Tarières

- Plain Bucket

- Seau 4 en 1

- Breaker or Hammer

- Pelle rétro

- Snow Bowlers

- Tiller

- Wheel Saw

- Cement Mixer

- Wood Chipper

- Fourchettes

Applications Of Skid Steer Loaders

As mentioned earlier, skid steer loaders also contain multiple applications. You can do various tasks at your construction site using this construction equipment. But this highly versatile machine can do multiple jobs only through the help of different attachments.

The interesting part to note about a skid steer machine is that sometimes people use it in place of a large excavator. The steer loader contains digging power equal to the large excavator. At the same time, it is also interesting to remember that the applications of a skid steer machine depend on its size. It exists in small, medium, and larger machine sizes.

Some applications of skid steer loader are given below:

Aménagement paysager

Skid steers are good at landscaping tasks, and you can also earn profit by performing landscaping tasks. Some tasks that come under the landscaping category are:

- Copeaux de bois

- Bêcher les arbres

- Creusement de tranchées

- Broyage de souches

Using bale spears and white pallet forks, you can also use them for farm work and warehouse tasks.

Excavation & Construction

Sometimes, it is tricky to choose the right equipment for excavation projects. But skid steers make it easy for you to perform excavation. However, it is important to remember that you must choose the right attachment to perform any job. Ripper, tiller, wheel saw, and trencher can be your best attachments.

Skid steers can fit easily with cement mixers and pavement millers. But make sure you choose the right weight and size. The machine may fluctuate on choosing an attachment larger than the required size or weight.

Trenching & Digging

Trenching and digging are the two most important applications of skid steers. It also contains attachments that are suitable for trenching and digging purposes. For example:

- Tarière

- Trench Digger

- Pelle rétro

All these attachments function differently, making it easy to complete the projects. However, make sure that your machine is serviced and maintained properly.

Clearing Snow

It is the least important application of skid steers. If you want to shovel the pesky snow from your driveway, You must consider a few things listed below:

- Use a snow blade attachment or snow bowler

- Do it with care and proper training.

Apart from all these applications, some other applications of skid steers are:

- Transport ou manutention de matériaux

- Développement de propriété ou de site

- Travaux souterrains

- Nivellement ou terrassement

- Démolition intérieure

- Creusement de trous de poteaux

- Enlèvement des débris

- Levage de charges lourdes, etc.

Tracked Vs. Wheeled Skid Steers

Skid steers are radial lift machines that you can find in two main types; tracked steers and wheeled skid steers. Let’s discuss both types below:

Tracked Skid Steers

Before digging into the explanation of tracked steers, it is important to note that these machines were invented after the wheeled version. The wheeled excavators had some serious limitations resulting in the invention of tracked skid steer loaders. They have a broader weight distribution due to the availability of two tracks.

The broader weight distribution of these skid steer loaders makes them ideal for snowy, wet, or muddy ground. They don’t sink into wet surfaces but rather float over them. If you want a smoother ride, you should select a tracked skid steer over a wheeled SSL.

However, you should think twice before using a tracked SSL on asphalt or concrete. A tracked SSL can easily tear up concrete or asphalt surface.

Wheeled Skid Steers

Wheeled SSLs can work perfectly on asphalt or concrete surfaces, unlike tracked skid steers. They have the ability to move faster on these types of surfaces. Therefore, you can cover more ground in less time by using the wheeled SSLs.

Wheeled skid steer loaders are capable of working on landscape surfaces in a much better way. The best part about them is that they are cheaper than tracked SSLs.

Note that the weight of this SSL is distributed on four contact points. It indicates that these SSLs can sink into snowy or muddy surfaces. But the best part is that you can maintain them easily. The reason behind cheap and easy maintenance is that wheels are less expensive than tracks.

Tire wear happens faster than tracks in the case of wheeled SSLs.

Simply put, tracked SSLs are the modern version of skid steer loaders, while wheeled SSLs are the older versions.

Advantages & Disadvantages Of Skid Steer Loader

Although skid steers are known for their popularity in construction sites, they have some pros and cons. You can read the as under:

Advantages

It is a versatile machine that can perform multiple tasks at your site. You can purchase it either in wheels or tracks. This machine consists of incredible features. Some advantages are:

- Great maneuverability

- Operator Comfort

- Great Visibility and Control

- Safety Features

- Easy to maintain

- Portable

- Easy to access

- Ease of use

- Attachments and flow rate

- Compact track loaders

Disadvantages

The disadvantages of skid steers can also be judged according to their types. For example:

- A wheeled skid steer has more chance of tires popping up on rough roads.

- Wheeled skid steer may also sink into the muddy ground.

- While a tracked SSL may damage a concrete or asphalt surface.

- Tracked SSLs require more cleaning and maintenance; hence, they are more expensive.

- Tracks are difficult to replace if they get damaged as compared to wheels.

Categories Of Skid Steer Loaders Based On Weight

Choosing the right size and weight of your SSL is better to ensure optimal performance. It is important to note that the features and specifications of each size may vary according to your manufacturers. Three main categories of SSL are:

Small Frame Skid Steers

These skid steers are also known as compact skid steers that you should prefer for minor projects. The small frame skid steers are ideal for projects like post-hole digging, moving materials, trenching, leveling, etc.

Medium Frame Skid Steers

The medium-frame skid steer is the right choice if you require tight maneuvering to get the job done. Using this skid steer, you can perform the jobs regarding the management and construction of materials. But you need to have a little more space to use this machine. It is because the machine carries a larger weight than a small frame skid steer.

Large Frame Skid Steers

These are larger machines that you use for heavy-duty projects. Larger demolition, grading work, and digging are some most common projects you carry with large-frame skid steers.

How To Choose The Right Skid Steer Loader?

It has always been a question for beginners to choose the right skid steer loader. But you can do it by focusing on some simple factors.

- First of all, you must choose the right size for your skid steer loader. And choosing the right size requires you to analyze the job and construction site conditions.

- Skid steer loaders are also named vertical lift machines or radial lift machines for a reason. They consist of lifts with different capacities. You must assess the lifts of the skid steer.

- You should know about the controls of a skid steer loader. It is important to be an expert at operating it. You can learn it by using the user manual.

- Perform an assessment of other functional features of your skid steer attachments.

- Make sure you deal with the right manufacturer and company.

Conclusion

These are the basics about the skid steer loaders you should know. As one ideal machine used for multiple applications, skid steer loaders make our work easier. If you plan to purchase one, or import one from China, Contactez-nous now. We are one of the leading construction machines suppliers based in China and can provide you with the best solutions.