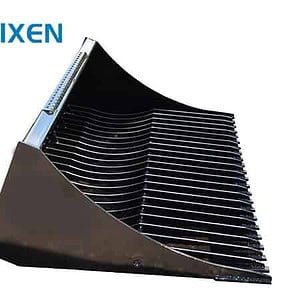

The 4-in-1 Combination Bucket is a highly efficient engineering accessory that integrates multiple functions. It is suitable for various construction machinery such as loaders and excavators. This bucket can significantly enhance work efficiency, reduce equipment procurement and operation costs, and is widely applied in numerous fields including construction, mining, and agricultural operations.

| Parameter Category | Detailed Parameter Content |

|---|---|

| Capacity Specifications | Offer a variety of options including 0.5 cubic meters, 0.8 cubic meters, 1.0 cubic meters, 1.2 cubic meters, 1.5 cubic meters, 2.0 cubic meters, 2.5 cubic meters, and 3.0 cubic meters. It can be flexibly selected according to the actual workload and the load-bearing capacity of the equipment. |

| Applicable Machine Models | Applicable to Caterpillar: 938H, 950H, 320D, 323D, etc.; Komatsu: WA380 – 6, WA470 – 6, PC200 – 8, PC220 – 8, etc.; Volvo: L90G, L120G, EC210B, EC240B, etc.; XCMG: LW300K, LW500K, XE215D, XE270D, etc.; Lonking: LG833N, LG855N, LG6225E, LG6235E, etc., different brands and models of loaders and excavators. |

| Material Information | The main body is made of high-strength wear-resistant alloy steel, such as Q690, NM400, etc. The yield strength can reach more than 690MPa, and the hardness reaches HB360 – 440, with excellent wear resistance and impact resistance. The cutting-edge part of the bucket is made of special wear-resistant surfacing materials to further enhance wear resistance and extend the service life. |

| Working Pressure | The normal working pressure range is 15 – 30 megapascals. It can be adjusted appropriately according to different working conditions and the hydraulic system of the equipment. The maximum allowable instantaneous pressure can reach 35 megapascals. |

| Hydraulic System | The hydraulic cylinders are equipped with high-quality seals to ensure good sealing performance and reliability, reducing hydraulic oil leakage. The hydraulic oil pipes are made of high-pressure rubber hoses, with a working pressure of up to 40 megapascals. The inner diameters are 10mm, 12mm, 16mm, etc., according to the flow requirements. |

| Connection Method | Adopt the standard pin connection method. The pin diameters are available in various specifications such as 40mm, 50mm, and 60mm to meet the connection requirements of different equipment. The connection parts are equipped with high-strength bolts to ensure the stability and safety of the connection. |

| Dimensions | Length: According to different capacity and functional requirements, the length ranges from 1800mm – 3000mm; Width: 1500mm – 2500mm; Height: 800mm – 1200mm. The specific dimensions can be customized according to actual orders. |

| Weight Parameters | The weight of the 0.5-cubic-meter bucket is approximately 800kg; the 0.8-cubic-meter bucket is about 1000kg; the 1.0-cubic-meter bucket is about 1200kg; the 1.2-cubic-meter bucket is about 1400kg; the 1.5-cubic-meter bucket is about 1600kg; the 2.0-cubic-meter bucket is about 2000kg; the 2.5-cubic-meter bucket is about 2400kg; the 3.0-cubic-meter bucket is about 2800kg (The above weights are approximate references, and the actual weights may vary slightly due to materials and structural designs). |

| Operating Angles | Digging angle: The maximum can reach 45° – 55°, which can be adjusted according to different operation requirements; Dumping angle: Generally between 40° – 60°, ensuring that the materials can be unloaded smoothly; Grabbing angle: Can be flexibly adjusted to adapt to grabbing materials of different shapes and weights. |

| Applicable Temperature Range | -20°C – 50°C. In extremely low-temperature environments, special hydraulic oil and protective measures can be used to ensure the normal operation of the equipment. In high-temperature environments, effective heat dissipation devices are equipped to prevent the hydraulic system from overheating. |

| Wear Resistance Index | The average wear rate of the wear-resistant layer of the bucket body does not exceed 0.5mm/1000 hours; the average wear rate of the cutting-edge wear-resistant layer does not exceed 1.0mm/1000 hours (tested according to standard working conditions). |

| Fatigue Life | Under the rated load and normal working conditions, after no less than 10,000 cycles of operation tests, there is no obvious deformation and damage to the structure, and there are no fatigue cracks in the key components. |

Besoin d'aide ? Parlez à un expert

No. 12111 Jingshi Road, Jinan, Chine

© Machines Hixen Tous droits réservés

WhatsApp nous

Veuillez remplir ce formulaire et nous vous répondrons dans les 8 heures ouvrables.

Veuillez remplir ce formulaire, notre catalogue complet de chaque produit en PDF peut être téléchargé immédiatement. Vos informations personnelles seront en sécurité.