Introduction

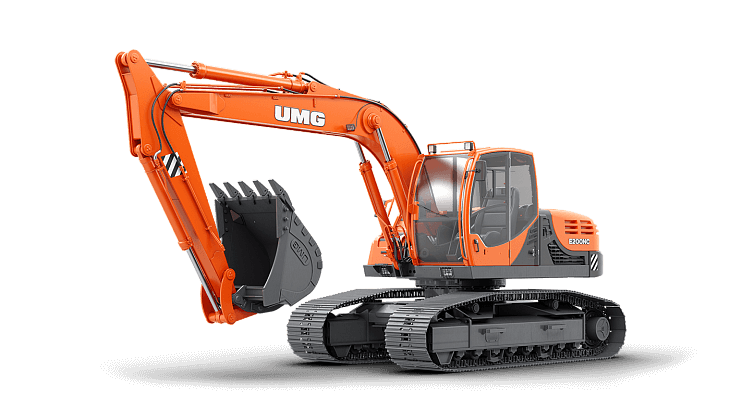

You know that suitable types of equipment are vital if you are involved in heavy-duty construction projects. Regarding excavation tasks, a crawler digger can be a valuable asset. These powerful machines can handle even the most challenging digging functions. Their tracks provide stability to work on sites with challenging topography.

One of the enormous benefits of using a crawler digger is its versatility. When equipped with a wide range of attachments, such as buckets, breakers, and grapples, they are helpful for various tasks, from digging foundations to demolishing buildings.

Crawler excavators are known for their durability, making them a wise investment for construction companies. They require minimal maintenance and ensure efficient and cost-effective performance. This blog will look at the benefits of using a crawler excavator.

Advantages Of Using A Crawler Digger For Heavy-Duty Construction Projects

If you’re in the construction industry, you know that excavators are essential equipment for many jobs. Among the different types of excavators, crawler excavators are the go-to choice for many construction projects. Here are some benefits of using a crawler excavator that you should know.

Firstly, crawler excavators are highly versatile. Crawler excavators can be used for various tasks, from digging trenches and foundations to moving large amounts of dirt or debris. They are beneficial in situations where access to the work area is limited or where space is tight. The tracks on the excavator allow it to move around on uneven terrain or through difficult-to-navigate regions, making it an excellent choice for challenging job sites.

Another advantage of crawler excavators is their digging depth and reach. They can excavate deeper and go farther than other types of excavators. Crawler excavators can complete jobs faster and with less effort, saving you significant time and labour costs and increasing the overall quality of your work.

In addition, crawler excavators are powerful machines that can handle heavy loads. They have solid engines and hydraulic systems that allow them to load and unload trucks, move materials, and build roads.

Crawler excavators are known for their durability and reliability. They are built to withstand harsh working conditions and can last many years with proper maintenance. The durability and reliability of crawler excavators make them a wise investment for any construction business looking for long-term equipment solutions.

The Versatility Of A Crawler Digger

Crawler excavators are one of the most versatile heavy equipment used in construction, mining, and other industrial applications. These machines have a powerful hydraulic system and tracks that allow them to traverse rough and uneven terrain, making them ideal for various applications.

One of the primary functions of a crawler digger is digging. With its powerful hydraulic system, the machine can dig through soil, gravel, and rock, making it an essential tool for excavating building, road, and bridge foundations. The crawler digger’s boom and arm system allows precision digging in tight spaces, making it ideal for urban construction projects.

A crawler digger can perform grading and levelling tasks. The machine’s blade attachment allows it to grade and level the ground. The crawler digger can have various branches, such as a ripper or compactor, to perform more specific grading and levelling tasks.

A crawler digger can also be used for demolition projects. With its powerful hydraulic system and the ability to rotate 360 degrees, the machine can quickly demolish buildings, bridges, and other structures. When equipped with attachments such as shears and hammers, making it an even more efficient demolition tool.

Finally, a crawler digger is capable of material handling. With its bucket extension, the machine can move large amounts of material from one location to another. The crawler digger can switch between various attachments, making it an efficient machine for multiple tasks.

Durability & Reliability Of A Crawler digger

Durability and reliability are crucial for a crawler digger, affecting its productivity, maintenance costs, and overall lifespan. Durability is the ability of a crawler digger to withstand wear, tear, and damage during prolonged and rigorous use. A durable crawler digger should be made of high-quality materials that resist corrosion, abrasion, and impact.

The chassis, tracks, boom, arm, and bucket are critical components that must be solid and sturdy to endure heavy loads and harsh working conditions. Inspect welding, bolts, and joints carefully to ensure that they can withstand stress and prevent leaks.

Reliability is the ability of a crawler digger to perform consistently and predictably without breakdowns, malfunctions, or unexpected downtime. A reliable crawler digger should have a robust engine, transmission, hydraulic system, and electrical system that can function smoothly and efficiently. It should also have easy-to-access maintenance points and a user-friendly control system.

The reliability of a crawler digger also depends on the quality of the components and parts used, such as filters, hoses, and bearings.

It is essential to perform regular maintenance and inspections to ensure the durability and reliability of a crawler digger.

Maintenance and inspections include checking the fluid levels and cleaning the air filters. Inspecting the tracks and undercarriage, lubricating the moving parts, and replacing worn-out components are also included. It is crucial to operate the excavator within its capacity and avoid overloading or overworking it, which can cause premature wear and tear.

Examples Of Heavy-Duty Construction Projects That Benefit From Crawler diggers

Crawler diggers are heavy-duty construction machines essential in the building and construction industry. Their unique features make them suitable for a wide range of construction projects. Here are some examples of heavy-duty construction projects that benefit from crawler diggers:

- Mining operationsCrawler diggers are widely used in mining operations. These machines are designed to work in rough and rugged terrains. They have the power to dig deep into the ground to extract minerals. The crawler diggers can dig open-pit mines, access underground mines, and transport extracted materials to processing plants.

- Road constructionCrawler diggers are also essential in road construction projects. They clear the ground, remove debris, and dig foundations for roadways and bridges. They are also used to excavate trenches for water, gas, and sewage pipelines.

- Demolition projectsOne of the advantages of crawler diggers in demolition work is their versatility. When fitted with specialised attachments, such as shears, hammers, and pulverisers, which allow them to demolish sections of a structure selectively, this is particularly useful when parts of a building need to be preserved, such as in historical buildings or buildings that are part of a larger complex.

- LandscapingCrawler diggers are also used in landscaping projects. Crawler diggers can dig ponds, create hills and valleys, and shape the land for aesthetic purposes. They also clear the planting ground and remove trees and other obstacles.

- Heavy lifting: Crawler diggers are particularly well-suited to heavy lifting tasks because of their stability and strength. They have broad, heavy-duty tracks that provide excellent traction on uneven terrain and are equipped with powerful engines that can generate high torque levels. Additionally, many models have a hydraulic system that allows operators to precisely control the movements of the attachments, making it possible to lift and move heavy objects with great accuracy.

Maintenance And Safety Tips For crawler diggers

crawler diggers are heavy-duty machines that are widely used in the construction industry. Crawler diggers are designed to perform various tasks such as digging, grading, demolition, and excavation. This article will discuss maintenance and safety tips to enhance performance and prevent accidents.

Conseils d'entretien :

- Regularly check the hydraulic system for leaks, cracks, and worn-out parts. The hydraulic system is an essential component of crawler diggers, and any issues can cause the machine to malfunction or fail.

- Check the engine oil level and other fluids, such as coolant and hydraulic oil, to ensure the correct level. Low levels of fluids can cause damage to the engine and other components.

- Clean the air filter regularly to prevent debris from entering the engine. The clean air filter will help prolong the engine’s life and ensure optimal performance.

- Inspect the tracks for any signs of wear and tear. Damage to these excavator parts can cause the machine to lose stability and affect the excavator’s performance.

Safety Tips:

- Always wear the appropriate personal protective equipment (PPE). It includes a hard hat, safety glasses, and steel-toed boots when operating a crawler digger.

- Before starting the machine, ensure that the area around the excavator is clear of any obstacles or people.

- Always use the seat belt and keep your hands and feet inside the cabin while operating the machine.

- Avoid overloading the machine, as it can cause it to tip over.

- Always follow the manufacturer’s instructions and guidelines for operating and maintaining the crawler digger.

Conclusion

In conclusion, a crawler digger can be invaluable if you undertake a heavy-duty construction project. Its versatility and power make it well-suited for various tasks, including digging, demolition, and material handling. Crawler diggers are designed to operate in challenging conditions, making them ideal for sites with uneven ground.

Their durability and reliability also mean they can withstand heavy use demands and last for years. Investing in a crawler digger for your construction project can help you save time and money, increase productivity, and achieve better results.