Are you unsure whether to use a bulldozer vs front end loader for your project? Choosing the right machine can be a challenge, but we’re here to help you decide!

Bulldozers and front end loaders serve different purposes on a construction site. While bulldozers are ideal for pushing heavy materials over rough terrain, front end loaders excel at lifting and moving materials. Understanding their strengths and differences will help you make an informed choice for your next project.

Let’s dive deeper into the differences between bulldozers and front end loaders to determine which one is right for your needs.

What Is a Bulldozer and What Does It Do?

Bulldozers are robust, tracked machines that are engineered to move substantial volumes of material with ease. These versatile workhorses are indispensable for a variety of tasks, including land grading, trench digging, and comprehensive land clearing.

Designed to handle heavy-duty operations, bulldozers excel in navigating rough and uneven terrain with their powerful engines and sturdy tracks. Their expansive blades enable them to swiftly shift soil, rocks, and other debris, making them a force to be reckoned with on construction sites.

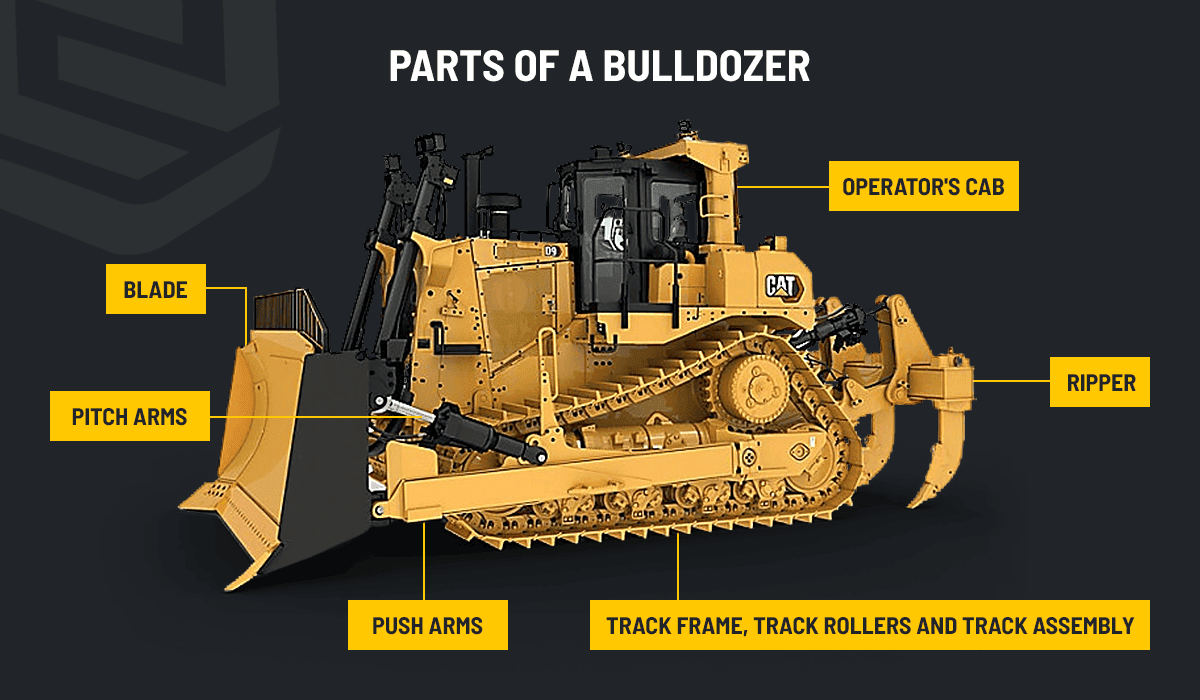

Available in a spectrum of sizes, bulldozers cater to a wide range of projects. From compact models tailored for residential jobs to behemoths suited for mining and massive construction endeavors, these machines are built to scale. Often, they are fitted with additional attachments such as rippers, which are indispensable for breaking up hard, compacted materials.

While front-end loaders are known for their versatility in loading and transporting materials, they do not possess the same level of pushing power that bulldozers are renowned for. This makes bulldozers the preferred choice when it comes to tasks that require the sheer force to move large amounts of material in a single direction.

What Are the Main Uses of a Bulldozer?

Bulldozers are indispensable on construction sites, renowned for their formidable strength and adaptability in tackling challenging environments.

These mighty machines are deployed in a variety of critical tasks such as land grading, where they meticulously shape the terrain to create a smooth and level surface; land clearing, where they swiftly remove vegetation and debris to prepare the site for development; road construction, where they carve out pathways and ensure the ground is even and stable for infrastructure; and trenching, where they dig deep channels for the installation of utilities.

In the demanding world of mining, bulldozers play a pivotal role in material handling, shifting large volumes of earth and rocks to access valuable resources. Their utility extends to projects characterized by rugged and uneven terrain, where their ability to navigate and manipulate the landscape is particularly valuable.

For instance, in road construction, bulldozers are the leader, clearing the way and smoothing out the ground to lay the foundation for a sturdy and durable road. They are also instrumental in demolition work, where they break down structures and push aside the resulting debris. In mining operations, bulldozers are tasked with moving debris and materials across rugged terrains, a task that requires their exceptional power and resilience. Overall, bulldozers are the workhorses of the construction and mining industries, relied upon for their ability to handle the toughest jobs with ease.

What Is a Front End Loader and What Does It Do?

A front-end loader is a versatile machine with a large bucket at the front end for scooping, lifting and moving materials such as dirt, sand and gravel.

Front-end loaders are ideal for tasks that require lifting and transporting materials. They are most commonly used in construction, agriculture and mining to load trucks or move piles of material.

Front-end loaders can work on more stable surfaces and are often used for tasks such as material loading and digging. Unlike bulldozers, they are not very good at pushing heavy materials over rough terrain, but are excellent at moving and stacking materials.

What Is a Front End Loader Used For?

Front-end loaders play a vital role in construction and material handling due to their ability to lift, move and stack materials.

Front-end loaders are used to transport loose materials such as dirt, sand, and gravel, and are ideal for loading trucks, clearing snow, or stacking materials at construction sites.

In addition to loading materials, front-end loaders can be used for a variety of applications, such as clearing snow, leveling roads, or digging shallow trenches. Their versatility makes them very useful in many construction, mining, and agricultural environments.

How Does a Front-End Loader Work?

A front-end loader, a marvel of modern engineering, functions through the use of sophisticated hydraulic systems that enable the bucket at its front to lift and maneuver materials with ease.

The hydraulic system of the front-end loader is the heart of its operation, powering the lifting arm and the bucket to perform the essential tasks of scooping, lifting, and dumping materials. The operator, seated in the cab, commands the loader’s movements with a joystick and pedals, providing precise control over the machine’s actions.

Front-end loaders embody a straightforward yet highly effective principle: the operator harnesses the loader’s hydraulic system to gather materials into the bucket. Once the bucket is filled, the operator lifts and transports the load to the desired location. The bucket’s dumping mechanism then comes into play, allowing for the efficient unloading of materials when required. This combination of capabilities lends front-end loaders their reputation for tasks that demand a high degree of precision in material handling. Their adaptability and control make them indispensable in a variety of applications, from construction sites to agricultural fields, where the careful manipulation of materials is key to success.

How to Operate a Front End Loader

Mastering the art of front-end loader operation entails gaining proficiency in controlling the bucket, the lift arm, and the machine’s traversal. The fundamental operations encompass scooping up materials, elevating the bucket to the desired height, and then transporting the load to a different site with care and accuracy.

To safely and effectively operate a front-end loader, one must become intimately acquainted with its hydraulic system, which is crucial for understanding how to balance the weight of the load. This knowledge is paramount for preventing the loader from becoming top-heavy or unstable. Additionally, operators must hone their skills in maneuvering the loader around obstacles and within confined spaces, which requires a keen sense of spatial awareness and dexterity.

Proper training is not just recommended but essential for front-end loader operators. It is the key to preventing accidents, ensuring efficient operations, and maintaining the safety of both the operator and the surrounding environment. Through comprehensive training, operators can develop the necessary skills to handle the loader with confidence, making them a valuable asset on any worksite.

Key Differences Between Bulldozers and Front End Loaders

Bulldozers and front-end loaders are both formidable pieces of heavy machinery, yet they possess distinct characteristics that render them more adept for various types of tasks.

The fundamental distinctions between these two workhorses stem from their core capabilities: bulldozers are engineered for the task of pushing, whereas front-end loaders are designed for lifting and loading. The tracks of a bulldozer provide it with the advantage of navigating rough terrain with ease, while front-end loaders deliver greater accuracy in the manipulation of materials.

Bulldozers boast superior traction and the muscular power needed to push substantial loads across challenging landscapes. In contrast, front-end loaders offer swiftness and agility, particularly when it comes to the lifting and transportation of materials. If your project entails extensive pushing and grading, a bulldozer’s might is likely the superior choice. However, for endeavors that demand meticulous material handling, the precision and dexterity of a front-end loader will prove more advantageous. Each machine excels in its own domain, making them indispensable tools in the right circumstances.

When to Choose a Bulldozer Over a Front End Loader?

Bulldozers excel in tasks like creating roads, leveling ground, and clearing land. Their powerful blades and tracks make them ideal for difficult terrain and large-scale construction.

In large-scale infrastructure projects, such as building highways or preparing land for construction, bulldozers provide the necessary power and durability. However, when the task shifts to loading or transporting materials over short distances, front end loaders become more efficient.

When to Choose a Front End Loader Over a Bulldozer?

Front end loaders are the go-to machine when you need to move materials quickly and efficiently over a stable surface.

Choose a front end loader for tasks involving material loading, stacking, and transport. It’s perfect for moving loose materials from one place to another or loading trucks and other equipment.

In construction sites with stable, level ground, a front end loader is ideal. Its ability to lift and carry materials with precision makes it an excellent choice for loading dirt, sand, and gravel, especially when working in confined spaces or near structures.

Bulldozer vs Front End Loader: Maintenance and Operating Costs

Understanding the maintenance and operational costs is crucial when choosing between a bulldozer and a front end loader for your project.

Bulldozers tend to have higher maintenance costs due to their tracks and heavy-duty components. Front end loaders generally have lower maintenance costs and are easier to operate, making them more cost-effective for short-term projects.

While bulldozers are built for heavy-duty tasks, their maintenance involves more complex systems and higher repair costs. Front end loaders, on the other hand, are generally more straightforward in their design and maintenance, leading to lower operational expenses. However, bulldozers may still be more cost-effective in large-scale, long-term construction projects due to their durability.

Summary

Choosing between a bulldozer and a front end loader depends on your specific construction needs. Each machine has its strengths, and understanding those will help you make the best choice.