Introduction

One of the common tools for any construction project is an excavator. Without the wheeled or crawler excavators, it is almost impossible to carry out the project’s work. Excavators can be used for a wide range of tasks. The tasks include digging, moving materials, landscaping, and even demolition. They also have industrial, mining, and river dredging applications.

A wide variety of excavators are available, each with its unique design and set of characteristics. The working environment and customer needs will determine the best type to use. While the most commonly types are crawler excavators and wheeled excavators. This article will introduce the differences between these two types of excavators.

What Is a Crawler Excavator?

As the name suggests, Crawler Excavator is a wheelless tracked vehicle. They require a hydrokinetic mechanism to lift massive loads and move along two gigantic tracks. They can move up and down using a chain wheel system. They work well on uphills and other forms of uneven surfaces.

Mines and large building sites benefit significantly from the use of crawler excavators. In addition, they have other applications in excavation, demolition, and trenching. At present, crawler excavators find widespread application in the farming sector. Their high traction efficiency makes them useful in a wide variety of other fields as well.

What Is a Wheeled Excavator?

Wheeled excavators move forward on the ground using wheels and tires. Wheeled excavators are multitasking machines used for standard excavation and transportation infrastructure. Excavators on wheels are just as powerful and versatile as their crawler counterparts.

The most noticeable difference is that they have wheels instead of tracks. Mostly in localities with excellent pavement, these machines find their applications. This enhances their mobility and efficiency. Since this is the case, they see a lot of use in urban construction and road maintenance. These excavators can be mounted or transported by trucks or boats.

Advantages of Crawler Excavators Over Wheeled Excavators

A crawler excavator’s strength is that it can dig or excavate without needing any extensive requirements. They may swing freely in all directions. The crawler crane has superior dynamic qualities and maneuverability compared to the wheeled crane. Its superior grading ability makes it useful in mining operations and swampy environments.

It functions safely on uneven surfaces and roads. This has led to an increase in the popularity of crawler excavators. Due to the crawler excavator’s lack of portability, a special transport cart could be designed for this purpose. Moreover, the crawler excavator’s overall performance is higher than that of the wheeled excavators.

Advantages of Wheeled Excavators Over Crawler Excavators

Wheeled excavators are extending further to dig deeper and closer to the machine. Reaching greater heights is possible with wheeled excavators. They can hop, swerve, and shimmy over, under, and around obstacles. In addition to being driven on roadways. Wheel excavators are movable and may be moved easily between construction sites.

Wheeled excavators can travel at rates of 40-50 kilometers per hour between construction sites. It functions safely on asphalt roads. The tire’s flexibility makes it stable and safe to drive on. Their lifting capability has often been higher than that of tracked machines.

Five Important Key Points to Make a Decision Between a Crawler & Wheeled Excavator

Wheel excavators and crawler excavators may appear to be identical. The only discernible difference between the two is the type of undercarriage each uses. However, before making a purchase, you should think carefully about each machine’s specific features and benefits. Demand for our construction firm is driven by the necessities of excavating, grading, and preparing sites.

Obviously, without the right excavator, completing your task would be a challenge. For example, the ground conditions can significantly affect whether or not you use a wheel excavator or a crawler excavator. Stability, maneuverability, attachment adaptability, and maintenance are additional concerns. When buying or renting a crawler or wheel excavator, we must consider these factors.

Ground Conditions Assessment at Your Job Site

The type of work must be assessed before opting on whether to use a crawler or wheel excavator. Would the major part of the machine’s work be on a single site or used for multiple sites? Whether it is required for the construction of roads and streets. There can be significant differences between choosing an excavation machine when working conditions are different.

You need to ensure the machines you choose can do the required job. Crawler excavators are exceptionally useful for digging and leveling uneven building sites. Typically, ground conditions relate to geology, hydrology, and soil condition. Anything that stands in the way of the construction project is an obstacle.

A snowstorm, for example, could affect which excavator would be used. Roads are impassable in flood- and snow-affected areas because of their slippery conditions. You can only get crawler excavators. The same approach is in desert environments. The best tool for the job is one that can move quickly and easily across the desert.

Wheeled excavators are designed to have rubber tires. They are the go-to tool for smoother surfaces like asphalt and concrete. Minimal ground damage is caused by driving these excavators on the ground’s surface.

Stability Needs Determination

The stability of machinery is important on any construction site. This becomes more important in heavy-duty digging and lifting tasks. The excavator’s stability is measured by its resistance to shocks and vibrations. Both the excavator itself and the weight of the rock in the bucket has an impact on stability.

Along with this, there are other elements, such as resistance to digging and inertia forces. These factors prevent movement and overturning. The ground contact of a crawler excavator is excellent. Having a tracked undercarriage makes the machine more steady. The wheels, dozer blades, and outriggers of a wheel excavator work together to ensure the machine stays in place.

When used for excavating, it is more steady. Additionally, the blade’s broad dozer bottom and parallel construction lessen the force exerted on the ground. The machine may be made level on slopes by separately adjusting each outrigger. Both crawler and wheel excavators are equally efficient diggers.

On the other hand, wheel excavators are just as stable as their crawler counterparts after their outriggers are retracted. Consequently, this allows wheel excavator operators to retain their machines’ original lifting capacity. Wheel excavators with four outriggers offer more support when chipping away or removing concrete.

Transportation Costs

Moving an excavator from one building site to another takes time and energy. To help us decide, we need to determine the transportation costs associated with each possibility. It’s possible that transporting an excavator from one job site to another is a routine procedure for many businesses.

There are a wide variety of vehicles required for transporting machinery. All these carriages have their specific uses. Depending on the logistics provider chosen, transportation costs can fluctuate widely. We must determine if a trailer built for a particular machine needs to be scaled up or down. Costs to transport larger excavators vary considerably.

It’s also crucial to find out if the right carrying truck is in your fleet. Transportation expenses in mining and quarrying operations are typically a one-time cost. The excavator will likely work exclusively at one location throughout its entire service life. For frequent material relocation, a wheel excavator may be preferable to a crawler model.

An excavator can be reached by vehicle in this area. Wheel excavators can be a cost-effective means of transport when roads are readily available. Low fuel economy is another factor that impacts transportation expenditures. All excavators consume a lot of energy in transit due to their weight.

Crawler-style vehicles consume more fuel than other types of vehicles because of their slower speed. The size and speed of the machine also determine the final cost. Maximum speeds for wheel excavators are 23 miles per hour. They are a good option if rapid movement is required on flat terrain.

On the other hand, they are not ideal for tasks such as clearing ditches or working on rough terrain. A Crawler may reach a top speed of 2.5 miles per hour. If road networks are easily accessible, the price may change. On the other hand, they are compact and cheap to transport through rough terrain.

Attachments

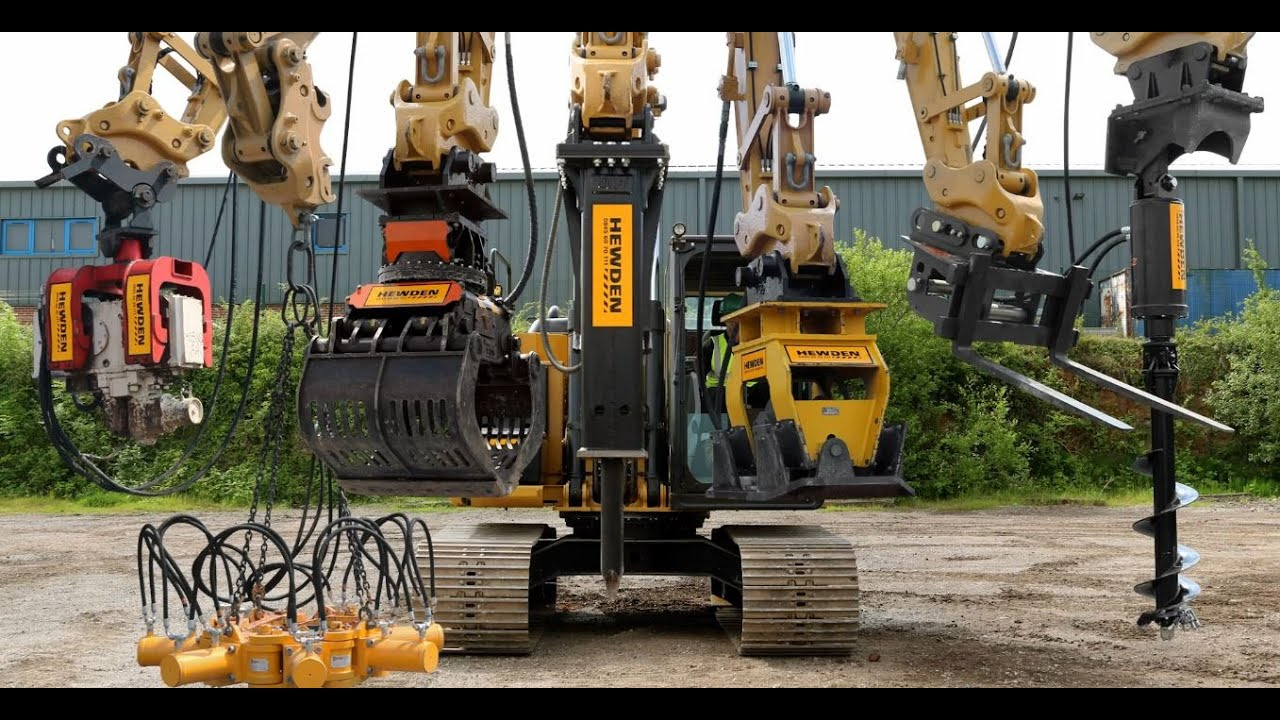

Excavators’ flexibility in adopting different attachments is one of their greatest strengths. To offer new services and gain autonomy on the job board. Easily switching between attachments is made possible by a high-quality coupling mechanism. A ditching bucket can stand in for a grading bucket in various grading situations.

Alternatively, we can adjust the buckets to fit the required trench width. The initial step is identifying the type that best accommodates our attachment needs. Tools that provide the greatest return in the shortest length of time should be given top priority. The cost of the necessary attachment should be taken into account as well.

Conclusion

When picking a specific type of excavator, there are numerous options available. The most prevalent types of excavators are wheeled and crawler models. At first glance, the movement mechanism is the only difference between the two. Nonetheless, there are several additional distinctions between them.

When choosing between crawler excavators and wheeled excavators, we must weigh their respective benefits. Other essential factors include working conditions, transportation, stability, and attachment flexibility.

If you wish to add an excavator to your collection of heavy machinery, we can certainly assist you.

Feel free to contact our heavy machinery experts, who will gladly answer your questions.