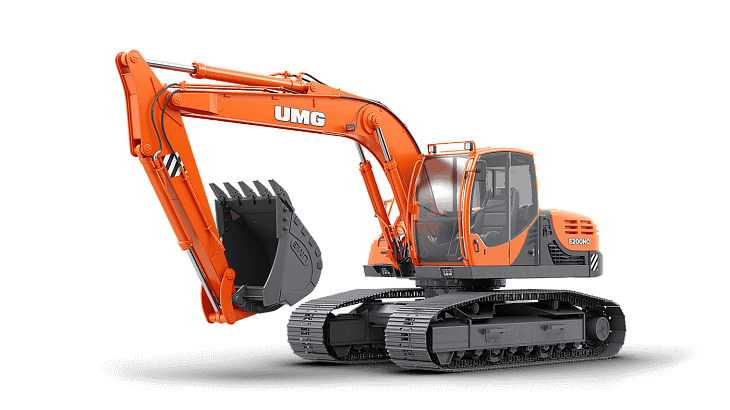

1. Excavator product structure

Generally, it is composed of a power unit, a transmission unit, a traveling unit and a working unit. Principle: Earth-moving machinery that uses a bucket to dig materials above or below the bearing surface and loads them into transport vehicles or unloads them to a stockpile. Self-propelled mining machinery that uses a bucket to shovel stripping materials or mineral products from the working surface and transports them to the unloading site for unloading. History: The first manual excavator has a history of more than 130 years. During this period, it has experienced a gradual development process from steam-driven bucket rotary excavators to electric-driven and internal combustion engine-driven rotary excavators, and fully automatic hydraulic excavators using electromechanical-hydraulic integration technology.

Due to the application of hydraulic technology, in the 1940s, there were suspended excavators equipped with hydraulic backhoes on tractors. In the early and mid-1950s, towed full-rotation hydraulic excavators and crawler-type full-hydraulic excavators were developed one after another. The initial trial-produced hydraulic excavators used hydraulic technology from aircraft and machine tools, lacked hydraulic components suitable for various working conditions of excavators, had unstable manufacturing quality, and incomplete supporting parts. Since the 1960s, hydraulic excavators have entered a stage of promotion and vigorous development. The number of excavator manufacturers and varieties in various countries has increased rapidly, and the output has soared. Between 1968 and 1970, the output of hydraulic excavators accounted for 83% of the total output of excavators, which was close to 100%.

2. Winter maintenance of excavators

- Preheating of the hydraulic device. When the hydraulic oil temperature is low, rapid operation will cause damage to the hydraulic device.

- The engine of the small excavator runs at medium speed, and the bucket is operated for preheating;

- The engine of the small excavator runs at medium speed, and the bucket is operated for preheating;

- Then, increase the engine speed to the highest level, so that the bucket and the dipper stick can work continuously for 5 minutes;

- At the same time, pay full attention to the safety of the surrounding environment during preheating operation. When the temperature is low, people’s reactions will be relatively slow, and it is necessary to prevent touching people and objects around during preheating.

- Preheating of small excavator engine: The first step after getting on the vehicle is to start the engine and run it at low speed for 5 minutes. At the same time, the following checks should be carried out during the preheating of the small excavator engine:

- Is the oil warning light off?

- Is there any oil or water leakage?

- Is the engine sound and exhaust color normal?

- Is the charging indicator light off?

- Are there any abnormalities in various parts of the machine?

- If the small excavator is idle in winter, it should be properly stored and maintained. It can only play the best performance when it is used again. The specific maintenance measures are as follows:

- Clean the dirt on the surface of the small excavator and check for loose fasteners.

- Check whether the antifreeze level and engine oil level are normal, check whether the engine oil quality is normal, and check the antifreeze level of the fuel.

- If the weather is particularly cold and the small excavator is down for a long time, please drain the engine coolant. At the same time, to prevent the battery from feeding, the battery must be removed and stored in a warm place.

- Start the engine once every period of time. If the antifreeze level and engine oil level are lower than the normal level, please add them to the normal level in time before starting. In cold weather, put the key in the preheating position until the preheating light is on (repeated preheating for many times), then start the engine, run at idle speed for 5-10 minutes, and then operate each cylinder without load for 5-10 times, each time 5-10MM less than the maximum stroke. Finally, make the engine speed the highest and quickly operate each cylinder 5-10 times, and operate the left and right rotation and forward and backward movement 3 times each. It can only operate normally when the system temperature rises to 50-80 degrees. Continue to operate all working devices for 5-10 minutes and then stop the engine.

- The diesel should be replaced with a -10 to -30 model, depending on the area. The more northerly the area is, the more diesel with – numbers should be added. In addition, the diesel filter should be replaced, the engine oil should be replaced with the locally applicable thickened engine oil, the oil filter should also be replaced, and the hydraulic system should be replaced in time if there is oil leakage. If conditions permit, the oil tank should be well insulated.

- The cooling system should carefully check whether the hose is aging and broken. If there is a problem, it should be replaced in time because these places are more likely to have problems in winter. If conditions permit, it is best to heat the water tank every day so that the engine can be started better, but be sure not to forget to drain the water. The reason why adding antifreeze is not recommended is that it is more difficult to start the engine in particularly cold areas.

3. Common faults of excavators

- 1. Causes of “shifting”

- Wear of the transmission mechanism The W4-60 excavator uses a mechanical shifting transmission mechanism, which relies on the sliding gear sleeve to move axially on the fixed gear sleeve and mesh with the driven gear of each gear to achieve shifting. During frequent shifting, the end faces of the gear teeth of the above meshing gears are easily worn into a cone, resulting in reduced meshing performance and “shifting”.

- Performance degradation of the self-locking mechanism To prevent the transmission from “shifting”, this type of excavator has self-locking steel balls and springs installed in the cover holes above the gear shift fork shafts of the gears II, III and IV, V, and in the gear shift forks I and reverse. When the elasticity of the positioning self-locking spring is weakened or broken, the self-locking performance of the self-locking mechanism will decrease until it disappears, causing the transmission to “shift”. At the same time, if the grooves on the positioning steel balls or the fork shafts are worn, the transmission may also “shift”.

- Improper adjustment of the shifting device. The transmission of this type of excavator adopts a mechanical manual shifting method. If the shift lever, longitudinal axis, transverse axis and vertical fixing screws are loose, the transmission may also “jump gears”.

- Sudden changes in external loads. Due to the working nature of the excavator and the design of the machine itself, sudden changes in external loads can also cause its transmission to “jump gears”. When the road surface is uneven, the machine is driving downhill or the driving route is improper, causing the external load to suddenly change, this sudden change in load will act on the gear meshing gear of the transmission through the wheels and the drive shaft, causing the gear meshing gear to disengage due to the axial thrust, causing the transmission to “jump gears”.

- Improper operation method. When the excavator is driving on a slope (especially downhill), if the operation is improper, it will also cause the transmission to “jump gears”.

- 2. Preventive measures

- Strictly follow the operating procedures and driving instructions to avoid “tooth knocking” when shifting gears to reduce wear on the gear pair.

- Strictly implement the maintenance system and strengthen the maintenance of the gear shift device. When the gear shift device rod system is improperly connected, it should be adjusted in time to ensure that the gear shift device performs well.

- Pay attention to the repair and maintenance of the self-locking mechanism. The positioning steel balls, springs and fork shafts that have reduced or lost their positioning efficiency should be repaired or replaced in time to keep the self-locking performance of the self-locking mechanism in good condition.

- When assembling the transmission, strictly follow the operating procedures to ensure that all parts of the transmission are correctly adjusted and properly tightened. When driving on a large downhill road, the driver should strictly follow the downhill action instructions and must not violate the rules.

- 3. Emergency response method During the driving process of the excavator, if the transmission “jumps gear”, the machine should be stopped in time (or continue to drive), and then the cause should be found and the fault should be eliminated. The specific method is:

- Emergency response method During the driving process of the excavator, if the transmission “jumps gear”, the machine should be stopped in time (or continue to drive), and then the cause should be found and the fault should be eliminated. The specific method is:

- If “jumps gear” occurs when driving uphill, the gear position can be placed in the low-speed position or the I gear position, and the machine can be stopped when it reaches the top of the slope to eliminate the fault; if the downshift fails or “jumps gear” occurs again, the machine should be stopped according to the action and requirements of the slope parking method, and then the fault should be eliminated.

- If the machine “jumps gear” when driving on a downhill slope, the gear should be placed in a high-speed position according to the shifting action instructions or “shift grabbing” (emergency downshifting) measures should be taken. After the machine reaches the bottom of the slope, stop the machine for inspection and troubleshooting. If “shifting up” or “shift grabbing” is unsuccessful or “shifting up” occurs again (at this time, it is in neutral), the driver can control the engine speed to medium speed (to prevent the engine from stalling), use the “brake” method to slide the machine to the bottom of the slope, and then troubleshoot. If “shifting up” or “shift grabbing” is unsuccessful or “shifting up” occurs again (at this time, it is in neutral), and the machine is on a steep downhill slope (at this time, the machine will “dive” to the bottom of the slope at a very fast speed), it should be stopped quickly according to the downhill stopping action instructions and requirements, and then the fault should be eliminated.

- Is the pilot pressure of the rotary operation within the normal range (normal pilot pressure is above 35KG);

- Is the rotary relief valve damaged, is the rotary relief pressure within the normal range (relief pressure: 280KG);

- Is the rotary main valve core switched to the right position, is the rotary valve core return spring broken;

- Is the distribution valve worn and damaged, causing internal leakage of the rotary motor;

- Is the rotary motor pump body and plunger worn and damaged, causing internal leakage of the motor; 6. Only the rotary action is slow and other actions are normal, so the hydraulic main pump and main relief valve faults can be ruled out;

4. Where to buy excavators

HIXEN excavators are cost-effective, with low after-sales and failure rates, making them a very good choice. Contact us for a quote.