Not understanding the key components of a bulldozer can lead to inefficient operation and costly repairs. Without proper knowledge, maintenance issues can arise, reducing the machine’s lifespan. This guide breaks down the essential parts of a bulldozer, helping you operate and maintain it effectively.

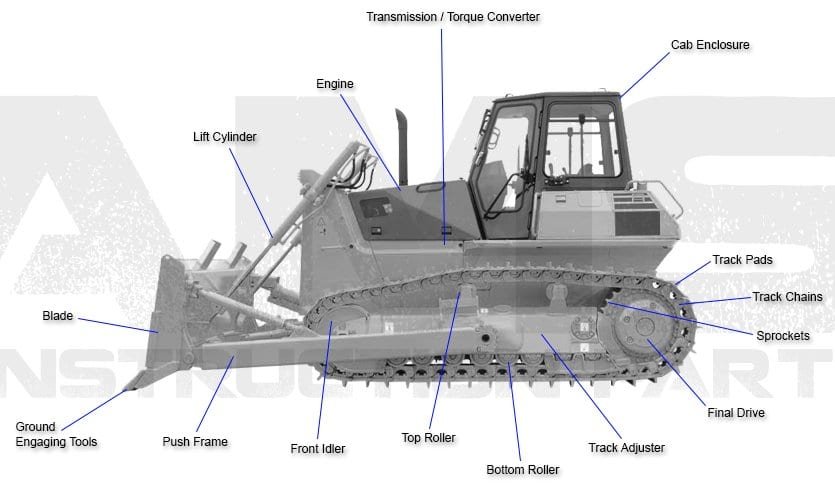

A bulldozer consists of key components such as the blade, undercarriage, tracks, engine, transmission, hydraulic system, and cab. Each part plays a crucial role in the machine’s performance. Understanding these components helps in efficient operation, maintenance, and troubleshooting.

Now, let’s explore each part of a bulldozer in detail.

What Is the Blade of a Bulldozer?

The most eye-catching feature of a bulldozer is its blade, which plays a crucial role in pushing materials, clearing debris, and leveling surfaces.

The blade is a large metal plate mounted at the front of the bulldozer. It is designed to push materials and comes in various types, each tailored to specific tasks. These types include straight blades (S-blades), universal blades (U-blades), and semi-U blades.

- Straight blade( S-blade), is ideal for precision grading and leveling. Its flat, straight shape allows for fine control and accuracy, making it perfect for tasks that require a high degree of precision.

- Universal blade(U-blade), is designed for moving large amounts of material. Its curved structure provides a larger capacity, enabling it to handle bulk materials more efficiently. This makes it suitable for tasks that involve heavy lifting and moving of materials.

- Semi-U blade combines the best features of both the S-blade and the U-blade. It offers a balance between capacity and control, making it versatile for a wide range of tasks. This hybrid design allows it to handle both precision work and heavy material movement effectively.

How Does the Bulldozer Undercarriage Work?

The undercarriage is a vital component of a bulldozer, as it supports the machine’s weight and ensures stability, allowing for efficient movement across various terrains.

The undercarriage consists of several key parts, including tracks, rollers, sprockets, and idlers, all of which work together to support movement and stability. Proper maintenance of these components is crucial to prolong their lifespan and ensure the bulldozer operates efficiently.

- Tracks: The tracks provide essential traction and stability, especially on rough and uneven terrain. They enable the bulldozer to move smoothly and securely, even in challenging conditions.

- Rollers: These components support the weight of the bulldozer and ensure that the tracks move smoothly. They play a critical role in maintaining the overall stability and balance of the machine.

- Sprockets: The sprockets are responsible for driving the tracks forward and backward. They engage with the track links to provide the necessary propulsion, ensuring that the bulldozer can move effectively.

- Idlers: The idlers maintain the correct tension in the tracks, which is essential for efficient operation. Properly tensioned tracks reduce wear and tear on the undercarriage components and ensure smooth, reliable movement.

Regular inspection and maintenance of the undercarriage components are essential to prevent breakdowns and ensure the bulldozer remains in optimal working condition.

What Is the Function of a Bulldozer Engine?

The engine is the heart of a bulldozer, providing the essential power that drives its operations. It is the powerhouse that enables the machine to perform its heavy-duty tasks with efficiency and reliability.

Bulldozers typically rely on high-powered diesel engines, which are designed to deliver the substantial torque needed for demanding construction and excavation tasks. These engines are built for durability and can withstand long hours of continuous operation. To keep the engine running smoothly and prevent breakdowns, regular maintenance is crucial. This includes routine oil changes and filter replacements, which help to keep the engine in top condition.

Here are some key aspects of the bulldozer’s engine and maintenance:

Diesel Engine:

Diesel engines are favored for their high torque output and durability. They provide the necessary power to move heavy loads and perform tasks that require significant force. The high compression ratio of diesel engines also contributes to their efficiency and longevity, making them well-suited for long work hours.

Cooling System:

The cooling system is essential for maintaining the engine’s temperature within a safe range. It prevents overheating, which can lead to engine damage and breakdowns. By ensuring that the engine stays cool, the cooling system helps to extend the engine’s lifespan and maintain its performance.

Maintenance Tips:

Regular maintenance is the key to keeping the engine in optimal condition. This includes:

- Oil Changes: Regularly changing the engine oil ensures that it remains clean and free of contaminants. Fresh oil provides better lubrication, reducing wear and tear on engine components.

- Fuel Filter Replacements: Replacing the fuel filter helps to prevent debris and impurities from entering the engine. This ensures that the fuel supply remains clean and the engine operates efficiently.

- Coolant Checks: Regularly checking and replacing the coolant helps to maintain the cooling system’s effectiveness. This prevents overheating and ensures that the engine remains at a safe operating temperature.

By following these maintenance tips, operators can significantly reduce the risk of engine breakdowns and ensure that their bulldozers remain reliable and efficient tools for heavy-duty tasks.

What Does the Bulldozer Transmission Do?

The transmission system in a bulldozer is crucial for ensuring smooth power delivery from the engine to the tracks. This system directly impacts the bulldozer’s speed and maneuverability, making it a key component for efficient operation.

Bulldozers typically use one of two types of transmissions: hydrostatic and torque converter. Each type offers distinct advantages and affects the machine’s performance in different ways.

Hydrostatic Transmission:

This type of transmission provides variable speed control, which is ideal for precision work. It allows the operator to make fine adjustments to the bulldozer’s speed, making it perfect for tasks that require accuracy and control. Hydrostatic transmissions are particularly useful in applications where the bulldozer needs to move slowly and steadily, such as grading or leveling surfaces.

Torque Converter Transmission:

This transmission is best suited for heavy-duty operations that require continuous power. It provides a smooth and efficient transfer of power from the engine to the tracks, enabling the bulldozer to handle large loads and perform demanding tasks without interruption. Torque converter transmissions are designed to handle high torque, making them ideal for tasks like pushing heavy materials or excavating.

Maintenance Tips:

To keep the transmission system operating efficiently, regular maintenance is essential. This includes:

- Fluid Checks: Regularly checking the transmission fluid levels ensures that the system remains well-lubricated. Clean fluid helps to reduce wear and tear on the components and prevents overheating.

- Filter Replacements: Replacing the transmission filters helps to keep the fluid clean and free of contaminants. This ensures that the transmission operates smoothly and efficiently, reducing the risk of breakdowns.

- Inspection for Leaks: Periodically inspecting the transmission system for leaks can help to identify potential issues early. Promptly addressing any leaks can prevent fluid loss and damage to the transmission components.

By following these maintenance tips, operators can ensure that their bulldozers remain reliable and efficient, regardless of the type of transmission system they use. Proper care of the transmission system is essential for maintaining the bulldozer’s performance and longevity.

How Does the Bulldozer Hydraulic System Work?

The hydraulic system is the backbone of a bulldozer’s versatility, controlling the blade, ripper, and other attachments with precision and efficiency. It enables smooth operation and allows for precise adjustments, making it an essential component for a wide range of tasks.

The hydraulic system operates by using pressurized fluid to power the movement of the blade, ripper, and other attachments. This fluid-based mechanism ensures that the bulldozer can perform its functions with both power and accuracy. Proper maintenance is crucial to ensure smooth performance and to prevent leaks, which can lead to costly repairs and downtime.

Here are some key components and maintenance tips for the hydraulic system:

Hydraulic Pump:

The hydraulic pump is the heart of the system, generating the pressure needed to move the hydraulic components. It ensures that the fluid is delivered at the right pressure, allowing the bulldozer’s attachments to function smoothly and efficiently.

Cylinders:

Hydraulic cylinders are responsible for converting the hydraulic pressure into mechanical motion. They enable the movement of the blade, ripper, and other attachments, providing the force needed to perform tasks such as pushing, lifting, and grading.

Maintenance Tips:

- Fluid Levels: Regularly check the hydraulic fluid levels to ensure that the system is adequately lubricated. Low fluid levels can lead to overheating and reduced performance, while contaminated fluid can cause damage to the components.

- Hose Inspections: Inspect the hydraulic hoses for signs of wear, damage, or leaks. Damaged hoses can lead to fluid loss and reduced efficiency, so it’s important to replace them promptly if any issues are detected.

- Leak Detection: Regularly inspect the entire hydraulic system for leaks. Even small leaks can lead to significant fluid loss over time, so early detection and repair are essential to maintain system integrity.

- Filter Replacement: Replace hydraulic filters regularly to keep the fluid clean and free of contaminants. Clean filters help to maintain the system’s efficiency and prolong the life of the hydraulic components.

By following these maintenance tips, operators can ensure that their bulldozers’ hydraulic systems remain in top condition, providing smooth operation and precise control for all tasks. Proper care of the hydraulic system is essential for maintaining the bulldozer’s performance and reliability.

What Are the Controls and Cab Features of a Bulldozer?

The cab is the command center of the bulldozer, where the operator controls the machine with the aid of advanced technology designed for ease of operation and enhanced efficiency.

Inside the cab, operators have access to a range of controls, including joysticks, pedals, and digital displays, which allow them to manage the bulldozer’s movement and blade operation with precision. Modern cabs are designed with the operator’s comfort in mind, featuring ergonomic seating and climate control systems to ensure a pleasant working environment.

Here are some key features of the cab that contribute to its functionality and operator comfort:

Joystick Controls:

These controls provide precise handling of the blade and other attachments. Joysticks offer intuitive operation, allowing the operator to make fine adjustments with ease, which is crucial for tasks that require accuracy and control.

Digital Displays:

Modern cabs are equipped with digital displays that show essential machine diagnostics. These displays provide real-time information on engine performance, hydraulic system status, and other critical data, helping the operator to monitor the bulldozer’s condition and make informed decisions.

Operator Comfort:

The cab is designed to enhance operator comfort and productivity. Air-conditioned cabs and ergonomic seating reduce fatigue, allowing operators to work efficiently for extended periods. Climate control systems ensure that the cab remains at a comfortable temperature, regardless of the external weather conditions.

Additional Features:

- Soundproofing: Many modern cabs are soundproofed to reduce noise levels, creating a quieter and more comfortable working environment for the operator.

- Visibility: The cab is designed to provide excellent visibility, with large windows and minimal blind spots. This allows the operator to have a clear view of the work area, enhancing safety and efficiency.

- Safety Features: Modern cabs often include advanced safety features such as roll-over protection structures (ROPS) and falling object protection systems (FOPS) to protect the operator in case of accidents.

By combining advanced technology with ergonomic design, the cab of a modern bulldozer not only enhances the operator’s comfort but also improves overall productivity and safety.

What Are Bulldozer Attachments and Their Uses?

Bulldozers are versatile machines that can be equipped with a variety of attachments to expand their functionality across different industries. These attachments enhance the bulldozer’s capabilities, making it a valuable tool in land clearing, construction, forestry, and more.

Here are some common bulldozer attachments and their uses:

Rippers

Rippers are essential for breaking up tough soil and rock. They are equipped with sharp, heavy-duty tines that can penetrate and shatter compacted ground, making it easier to move and grade. This attachment is particularly useful in construction and land development projects where hard, rocky terrain needs to be prepared for building or excavation.

Winches

Winches are powerful tools that assist in pulling heavy loads. They are often used in forestry to drag logs and in construction to move large materials or equipment. The winch’s ability to exert significant pulling force makes it an invaluable addition for tasks that require heavy lifting or moving.

Root Rakes

Root rakes are designed to clear tree roots and debris efficiently. These attachments are equipped with sturdy teeth that can effectively remove roots, stumps, and other obstacles from the ground. Root rakes are particularly useful in land clearing and forestry operations, where clearing large areas of land is necessary.

Grapple Buckets

Grapple buckets are used for picking up and moving large objects, such as logs, rocks, and debris. They are equipped with a set of claws that can grip and hold materials securely, making them ideal for forestry and land clearing tasks.

Angle Blades

Angle blades can be adjusted to different angles, allowing for more precise grading and leveling. They are particularly useful in construction projects where fine control over the grading process is required.

Snow Plows

Snow plows are designed to clear snow and ice from roads, parking lots, and other surfaces. They are equipped with a large, curved blade that can push snow to the side, making them essential for winter maintenance operations.

By equipping bulldozers with these versatile attachments, operators can tackle a wide range of tasks with greater efficiency and precision. Whether it’s breaking up tough terrain, pulling heavy loads, or clearing debris, the right attachment can significantly enhance the bulldozer’s capabilities and make it a more versatile tool in any industry.

Parts of A Bulldozer Summary

A bulldozer consists of essential components like the blade, undercarriage, engine, transmission, hydraulic system, cab, and attachments. Understanding each part helps improve efficiency and maintenance.