Hydraulic Thumb- Enhance Your Excavator’s Grabbing Power

The Hydraulic Thumb is a specialized attachment for excavators, designed to greatly improve the machine’s ability to grip, handle, and manipulate materials. This tool is essential for tasks involving the lifting, holding, and loading of debris, rocks, logs, and other materials. By providing controlled clamping power, the hydraulic thumb transforms your excavator into a versatile, high-performance tool, enabling efficient handling and reducing the need for additional machinery.

Additional information

What is a Hydraulic Thumb?

A Hydraulic Thumb is a mechanical attachment that works in conjunction with an excavator’s bucket to provide enhanced gripping capabilities. It consists of a thumb-like arm, which is powered by hydraulic cylinders, allowing the thumb to move in and out to grab, secure, and manipulate objects. This tool is often used for tasks where precise control over materials is essential, including demolition, forestry, construction, and material handling.

Key Benefits Of Hydraulic Thumb

- Enhanced Gripping Power: Allows the excavator to securely hold and manipulate materials that would otherwise be difficult to handle with a bucket alone.

- Increased Versatility: Useful for lifting, loading, clamping, and even sorting materials in various applications.

- Improved Efficiency: Reduces the need for additional equipment, improving overall operational productivity and cost-effectiveness.

- Durability: Designed to withstand tough environments, offering longevity and reliable performance in demanding tasks.

- Easy Integration: The hydraulic thumb can be easily installed on most excavators and works in sync with the machine’s existing hydraulic system.

Parameters Of Hydraulic Thumb

| Parameter | Description |

|---|---|

| Material | High-strength steel or alloy for durability |

| Weight | Varies based on size (typically 150kg – 500kg) |

| Maximum Gripping Force | 5 to 30 tons (depending on thumb size and excavator capacity) |

| Mounting Type | Pin-on, quick coupler, or custom mounts |

| Hydraulic Pressure | Typically 250 bar or as required for specific tasks |

| Tine Length | Adjustable based on application and machine size |

| Compatibility | Suitable for excavators from 5 tons to 50 tons |

| Width | Typically ranges from 0.8m to 3m |

| Cylinder Bore Size | 50mm to 100mm (depending on application and excavator size) |

| Control Type | Manual or hydraulic control (via excavator’s hydraulic system) |

| Operating Temperature | -20°C to +60°C (for extreme weather conditions) |

Excavator Thumb Working Video

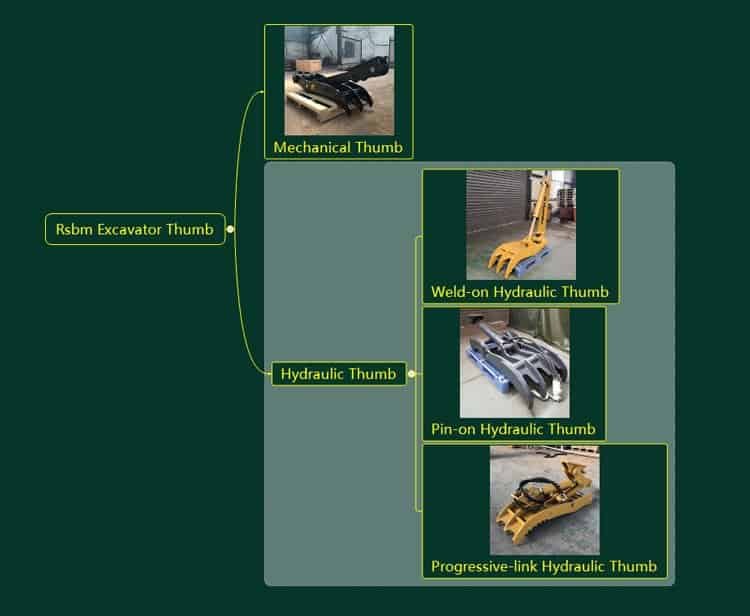

Types Of Hydraulic Thumb

- Standard Hydraulic Thumb

The most common type, designed for general excavation and material handling, ideal for smaller to medium-sized tasks. - Heavy-Duty Hydraulic Thumb

Built for high-performance tasks involving heavy loads, such as demolition, forestry, or construction, suitable for large excavators. - Adjustable Hydraulic Thumb

Features an adjustable arm for varying material sizes and handling requirements. Perfect for dynamic tasks in unpredictable environments. - Mechanical and Hydraulic Combination Thumb

Combines the benefits of a hydraulic thumb with mechanical support, offering a more robust solution for handling exceptionally large or heavy materials.

Features Of Hydraulic Thumb

- Fully Adjustable Jaw: The hydraulic thumb’s jaw can be adjusted for different gripping capacities, enabling a range of material handling tasks.

- Automatic Locking Mechanism: Some models feature an auto-locking system that secures materials once grabbed, ensuring a firm hold during transportation.

- 360° Rotation (Optional): Certain hydraulic thumb models offer 360° rotation for superior precision and maneuverability in tight spaces.

- Durable Coatings: Many models are treated with anti-corrosion coatings to ensure long-lasting performance even in harsh conditions.

- Easy Maintenance: Designed for easy servicing, hydraulic thumbs require minimal upkeep, ensuring reliability during heavy-duty applications.

Common Applications of Hydraulic Thumb

- Demolition: Efficiently grab and lift debris, such as concrete, bricks, and steel, reducing reliance on other machines.

- Landscaping: Helps in handling rocks, logs, and trees during excavation, making landscaping projects more manageable.

- Forestry: Ideal for tree handling, from felling to moving large logs and trunks, improving productivity in forestry operations.

- Construction: Ideal for lifting and moving building materials, such as steel beams and pre-cast concrete, in construction sites.

- Material Handling: Works well in waste management and recycling operations, assisting in the sorting and moving of materials.

Customized Colour

- What size excavator do I need for a hydraulic thumb?

Hydraulic thumbs are compatible with excavators ranging from 5 tons to 50 tons. It’s important to match the size of the thumb with your excavator for optimal performance. - Can I use a hydraulic thumb for lifting heavy materials?

Yes, hydraulic thumbs are designed to handle heavy materials like rocks, logs, and debris, depending on the thumb’s size and the excavator’s lifting capacity. - How does a hydraulic thumb work with my excavator?

The hydraulic thumb connects to your excavator’s hydraulic system and is operated using the same controls that manage the arm and bucket, allowing precise control over gripping and release. - Is the hydraulic thumb easy to install?

Most hydraulic thumbs are designed for easy installation, with options for quick couplers or pin-on mounts, ensuring compatibility with your excavator. - What is the lifespan of a hydraulic thumb?

With proper maintenance and care, a hydraulic thumb can last for many years, even in demanding environments. Regular inspection and servicing are recommended to ensure longevity. - Can I use the hydraulic thumb in cold or hot weather conditions?

Yes, hydraulic thumbs are designed to work in a wide range of temperatures, typically from -20°C to +60°C, but it’s important to check the manufacturer’s guidelines for extreme conditions.

Contact Us

Featured Products

Over the years, HIXEN has been focusing on technology innovation and precision manufacturing. Started from mini excavators, now the medium excavator, loader and skid steer loader are all quite mature. Take a view of the featured products, and get a instant quote immediately if you have the interest.